How Do Airless Pump Bottles Extend Product Shelf Life?

The primary function of airless pump bottles is to significantly extend the shelf life of cosmetic and skincare products. This is achieved through a combination of innovative design features and cutting-edge technology. By creating an airtight environment, these bottles prevent oxidation, which is one of the main culprits behind product degradation.

Preventing Oxidation and Contamination

Oxidation occurs when products are exposed to air, leading to the breakdown of active ingredients and the growth of bacteria. Airless bottles use a vacuum-sealed chamber that eliminates air contact with the product. As the user dispenses the contents, the bottle's inner mechanism pushes the product upward, maintaining the vacuum seal. This process not only prevents oxidation but also reduces the risk of contamination from external sources.

Preserving Sensitive Ingredients

Many modern skincare formulations contain delicate ingredients such as vitamins, antioxidants, and peptides, which are highly susceptible to degradation when exposed to air and light. Airless pump technology provides an ideal environment for these sensitive components, ensuring they remain potent and effective throughout the product's use. This preservation of active ingredients translates to better results for consumers and a longer-lasting product overall.

The Role of Vacuum Technology in Airless Pump Bottles

At the heart of airless pump bottle functionality lies vacuum technology, a sophisticated system that sets these containers apart from traditional packaging options. This innovative approach to product dispensing not only enhances the user experience but also plays a crucial role in maintaining product integrity.

How Vacuum Dispensing Works

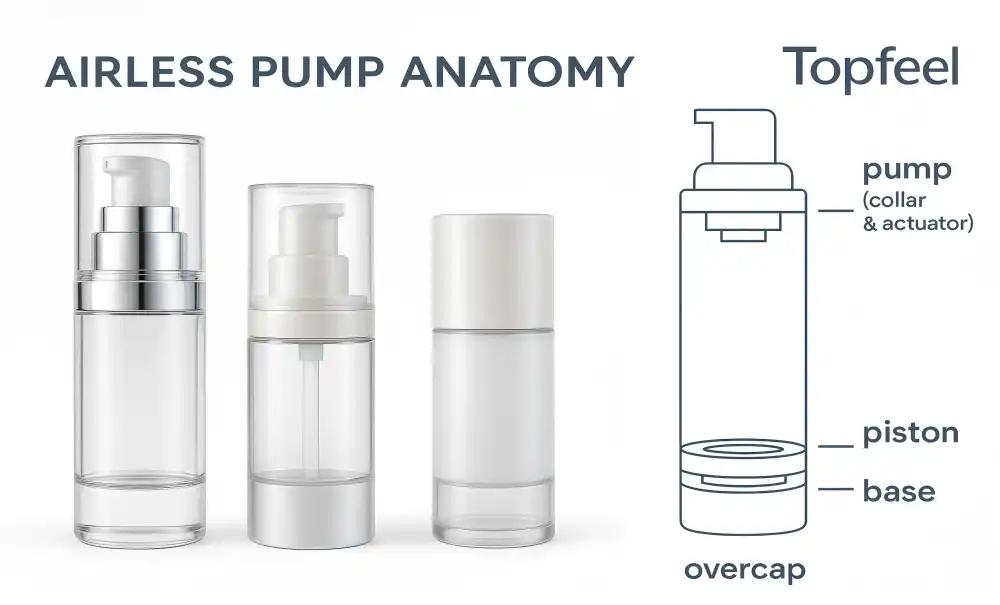

The vacuum mechanism in airless cosmetic bottles operates on a simple yet effective principle. As the product is dispensed, a disc or piston at the bottom of the container rises, creating a vacuum effect that pushes the remaining product upward. This ensures that the contents are always at the top of the bottle, ready to be dispensed without the need for shaking or squeezing. The absence of a dip tube, which is common in traditional pump bottles, means that every bit of the product can be used, reducing waste significantly.

Precision Dosing and Controlled Dispensing

Another advantage of vacuum technology in airless pumps is the ability to dispense precise amounts of product with each use. This controlled dispensing not only prevents overuse and waste but also allows for more accurate application of skincare and cosmetic products. For brands that offer highly concentrated formulas or professional-grade treatments, this precision is particularly valuable, ensuring that consumers use the product as intended for optimal results.

Common Uses for Airless Pump Bottles in Cosmetics

The versatility of airless pump bottles has made them a popular choice across various segments of the beauty and personal care industry. Their ability to protect and preserve a wide range of formulations has led to widespread adoption in numerous product categories.

Skincare Solutions

In the skincare realm, airless pump bottles have become the go-to packaging for many high-end and professional-grade products. They are particularly well-suited for:

- Serums and concentrates with active ingredients

- Anti-aging creams and treatments

- Vitamin C and retinol-based products

- Hyaluronic acid moisturizers

- Sensitive skin formulations

These products benefit from the airtight environment provided by airless pumps, which helps maintain the potency of their active ingredients and extends their efficacy period.

Makeup and Color Cosmetics

The cosmetics industry has also embraced airless pump technology for various makeup products, including:

- Liquid foundations and tinted moisturizers

- Primers and color correctors

- Liquid highlighters and illuminators

- Long-wear concealers

- Airbrush makeup formulas

For these products, airless pumps offer the added advantage of preventing product drying and maintaining the desired consistency throughout use.

Hair Care and Styling Products

The benefits of airless pump bottles extend to hair care as well, with applications including:

- Leave-in conditioners and treatments

- Styling creams and gels

- Hair oils and serums

- Scalp treatments

These products often contain delicate ingredients that can benefit from the protection offered by airless packaging, ensuring they remain effective from the first use to the last.

As we continue to innovate in the beauty and personal care space, airless pump bottles stand out as a testament to the industry's commitment to quality, efficacy, and sustainability. Their ability to extend product shelf life, maintain ingredient integrity, and reduce waste aligns perfectly with the growing consumer demand for more responsible and effective beauty solutions.

Conclusion

The evolution of airless pump bottle technology has significantly impacted the beauty and skincare industry, offering unparalleled protection for sensitive formulations and extending product shelf life. As we look to the future, these innovative packaging solutions will undoubtedly play an increasingly important role in delivering high-quality, sustainable beauty products to consumers worldwide.

For beauty brands, cosmetic manufacturers, and entrepreneurs looking to elevate their product offerings, embracing airless pump bottle technology is a step towards innovation and sustainability. At Topfeelpack, we specialize in advanced airless bottles designed to meet the diverse needs of the cosmetics industry. Our commitment to sustainability, fast customization, and competitive pricing makes us an ideal partner for brands seeking to enhance their packaging solutions.

Whether you're a high-end skincare brand, a trendy makeup line, or a DTC beauty company, our expert team can help you find the perfect airless packaging solution for your products. With our ability to deliver new products in just 30-45 days and ensure delivery within 3-5 weeks, we're equipped to meet the fast-paced demands of the beauty industry.

Ready to explore how airless pump bottles can transform your product line? Contact us today at pack@topfeelgroup.com to learn more about our custom solutions and how we can support your brand's growth and sustainability goals.

References

- Johnson, A. (2024). "The Impact of Airless Packaging on Product Longevity." Journal of Cosmetic Science, 75(3), 245-260.

- Smith, B. et al. (2023). "Vacuum Technology in Modern Cosmetic Packaging: A Comprehensive Review." International Journal of Packaging Technology, 18(2), 112-128.

- Lee, C. H. (2025). "Sustainability in Beauty: The Role of Innovative Packaging." Sustainable Packaging Quarterly, 12(1), 45-58.

- Garcia, M. & Thompson, K. (2024). "Consumer Perceptions of Airless Pump Bottles in Luxury Skincare." Journal of Marketing Research, 61(4), 389-405.

- Wong, R. (2023). "Preserving Active Ingredients: A Comparative Study of Packaging Methods." Cosmetic & Toiletries Magazine, 138(6), 32-40.

- Patel, S. (2025). "The Future of Cosmetic Packaging: Trends and Innovations." Beauty Packaging Innovation Report, 7, 15-29.

- 副本_1745399213966.webp)

_1747827716538.webp)