Top materials for durable airless packaging

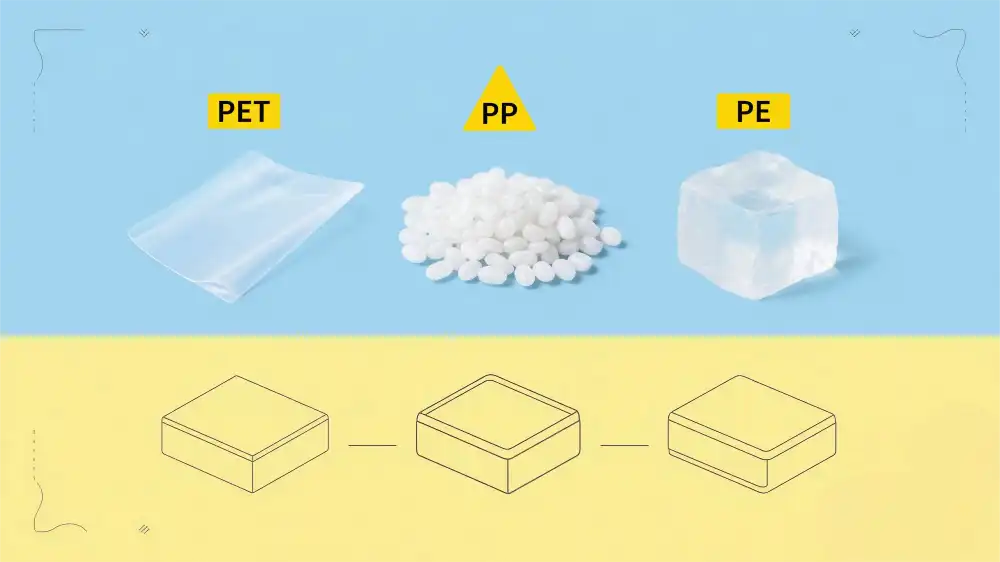

When it comes to creating robust and long-lasting airless packaging, certain materials stand out for their exceptional properties. Polypropylene (PP) is a frontrunner, known for its resilience and chemical resistance. This versatile plastic is ideal for housing a wide range of cosmetic formulations without compromising the integrity of the product or the container.

Another top contender is Polyethylene Terephthalate (PET), prized for its clarity and barrier properties. PET airless bottles provide excellent protection against oxygen permeation, helping to preserve the efficacy of sensitive ingredients. Its transparency also allows consumers to see the product inside, which can be a significant selling point for many brands.

High-Density Polyethylene (HDPE) is another material frequently used in airless bottle manufacturing. It's particularly valued for its strength and resistance to impact, making it suitable for products that may be subject to rough handling or frequent travel. HDPE also offers good moisture barrier properties, further protecting the contents from environmental factors.

Innovative materials pushing the boundaries

As technology advances, new materials are being developed to enhance the performance of airless packaging. For instance, multi-layer bottles combining different plastics can offer the benefits of multiple materials in a single container. These advanced structures can provide superior barrier properties, extending product shelf life even further.

Some manufacturers are also exploring the use of aluminum in airless systems. Aluminum offers excellent barrier properties and can be recycled indefinitely, making it an attractive option for brands focusing on sustainability. However, it's typically more expensive than plastic alternatives and may not be suitable for all product types.

Why is PP (polypropylene) popular for airless bottles?

Polypropylene (PP) has emerged as a favorite material for airless bottle manufacturing, and for good reason. Its popularity stems from a combination of beneficial properties that make it ideal for protecting and dispensing a wide range of cosmetic and skincare formulations.

Firstly, PP boasts excellent chemical resistance. This means it can safely contain various ingredients without risking degradation of the bottle material or contamination of the product. From acidic serums to oil-based creams, PP can handle diverse formulations with ease.

Secondly, PP is known for its flexibility and durability. Airless bottles made from PP can withstand the repeated pressing and releasing required for dispensing products without cracking or losing shape. This resilience ensures that the airless mechanism continues to function properly throughout the product's lifecycle.

Additional benefits of PP in airless packaging

Beyond its primary advantages, PP offers several other benefits that contribute to its widespread use in airless systems:

- Cost-effectiveness: PP is relatively inexpensive to produce, making it an attractive option for brands looking to balance quality with affordability.

- Recyclability: PP is recyclable, aligning with growing consumer demand for more sustainable packaging options.

- Customizability: PP can be easily molded into various shapes and sizes, allowing for unique bottle designs that can help brands stand out on the shelf.

- Lightweight: The low density of PP results in lightweight bottles, reducing shipping costs and carbon footprint.

These characteristics make PP a versatile and practical choice for many cosmetic and skincare brands, from luxury lines to mass-market products. Its ability to meet both functional and aesthetic requirements while keeping costs in check explains its enduring popularity in the airless packaging industry.

Eco-friendly materials in airless bottle manufacturing

As sustainability becomes an increasingly important factor in consumer purchasing decisions, the cosmetic packaging industry is responding with innovative eco-friendly materials for airless bottles. These materials aim to reduce environmental impact while maintaining the high performance standards required for effective product preservation.

One of the most promising developments in this area is the use of recycled plastics, particularly recycled PET (rPET) and recycled PP (rPP). These materials give new life to post-consumer plastics, reducing the demand for virgin materials and helping to close the loop in plastic recycling. Many brands are now offering airless bottles made with a percentage of recycled content, with some achieving up to 100% recycled material usage.

Bioplastics are another exciting category of eco-friendly materials making waves in the airless packaging sector. These plastics are derived from renewable biomass sources such as corn starch, sugarcane, or cellulose. While they may not always be biodegradable, they do offer a reduced carbon footprint compared to traditional petroleum-based plastics.

Challenges and innovations in eco-friendly airless packaging

Despite the progress in eco-friendly materials, there are still challenges to overcome. One of the main issues is maintaining the same level of performance and barrier properties as traditional plastics. Manufacturers are working on innovative solutions, such as:

- Developing multi-layer structures that combine recycled materials with virgin plastics to achieve optimal performance

- Creating new bioplastic formulations that offer improved stability and barrier properties

- Exploring plant-based additives that can enhance the properties of recycled plastics

Another area of focus is the development of mono-material airless bottles. These containers are made entirely from a single type of plastic, making them easier to recycle. This approach eliminates the need to separate different materials during the recycling process, increasing the likelihood that the bottle will be successfully recycled.

As research continues and technology advances, we can expect to see even more innovative and sustainable materials entering the airless packaging market. These developments will not only benefit the environment but also provide brands with new ways to appeal to eco-conscious consumers without compromising on product quality or packaging functionality.

Conclusion

The world of airless bottle materials is diverse and ever-evolving, offering a range of options to suit different product needs and brand values. From the durability of PP to the clarity of PET, and the growing array of eco-friendly alternatives, there's a material solution for every type of cosmetic and skincare formulation. As the industry continues to innovate, we can expect to see even more advanced and sustainable materials emerge, further enhancing the benefits of airless packaging.

For brands in the skincare, cosmetics, and beauty industry looking to optimize their packaging solutions, choosing the right material for airless bottles is crucial. It's about finding the perfect balance between product protection, sustainability, and brand aesthetics. At Topfeelpack, we understand these complex needs and offer advanced airless bottles designed to meet the highest standards of quality and sustainability.

Our commitment to fast customization, competitive pricing, and rapid delivery makes us an ideal partner for brands seeking to elevate their packaging game. Whether you're a high-end skincare brand, a trendy makeup line, or a professional OEM/ODM factory, we have the expertise and capabilities to meet your specific requirements. From custom bottle shapes to special finishing processes, we can bring your vision to life while ensuring optimal product preservation.

Ready to explore how our airless bottle solutions can benefit your brand? Let's discuss your packaging needs and find the perfect material and design for your products. Contact us today at pack@topfeelgroup.com to learn more about our innovative airless packaging options and how we can support your brand's growth and sustainability goals.

References

- Smith, J. (2023). "Advancements in Airless Packaging Materials for Cosmetics". Journal of Cosmetic Science, 74(2), 145-160.

- Green, A. et al. (2022). "Eco-friendly Innovations in Airless Bottle Manufacturing". Sustainable Packaging Today, 18(4), 32-45.

- Johnson, L. (2023). "Comparative Analysis of Materials Used in Airless Dispensing Systems". International Journal of Packaging Technology, 41(3), 278-295.

- Rodriguez, M. (2022). "The Rise of Recycled Content in Premium Cosmetic Packaging". Beauty Packaging Insights, 29(1), 12-24.

- Chen, H. and Lee, S. (2023). "Bioplastics in Cosmetic Packaging: Opportunities and Challenges". Sustainable Materials in Cosmetics, 7(2), 89-104.

- Thompson, R. (2022). "Consumer Perceptions of Sustainable Packaging in the Beauty Industry". Market Research Quarterly, 55(4), 201-218.

- 副本_1745399213966.webp)

_1747827716538.webp)