The Science Behind Airless Pumps: How They Block Oxygen and Preserve Actives

Airless pumps are marvels of modern packaging engineering, designed to combat one of skincare's greatest enemies: oxidation. At the heart of their functionality lies a simple yet effective principle: create a barrier between the product and the outside air. This is achieved through a clever mechanism that dispenses the product without allowing air to enter the container.

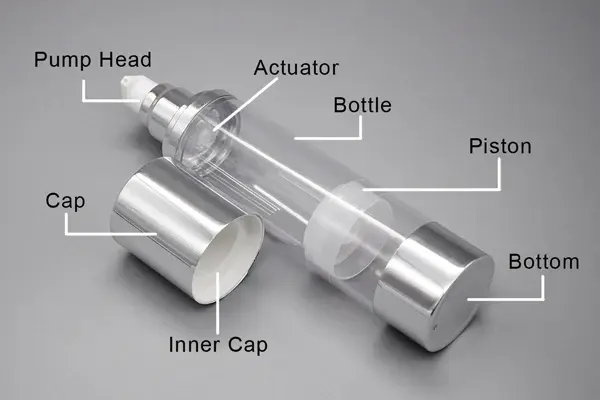

The Inner Workings of Airless Technology

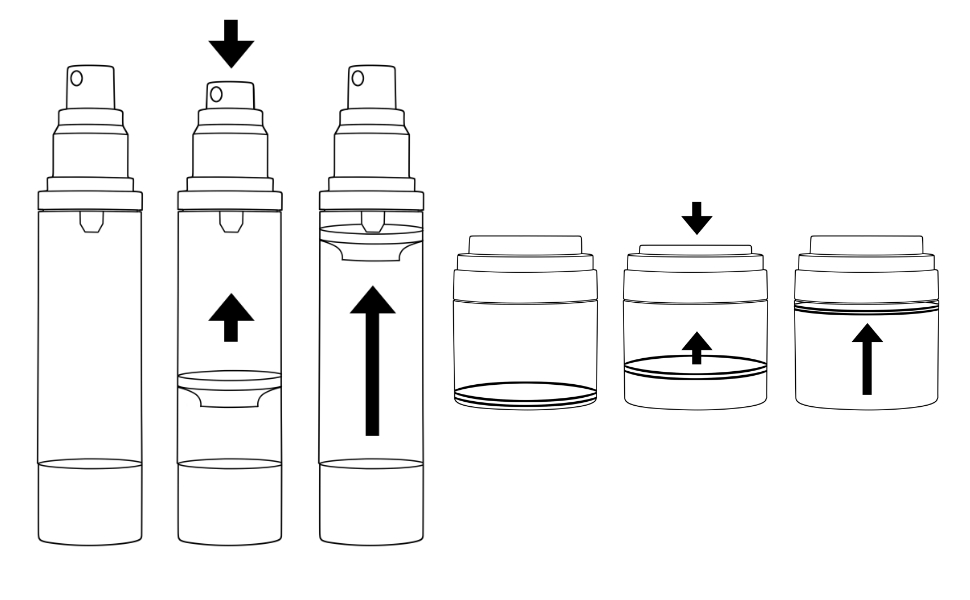

When you press the pump, a vacuum is created inside the bottle. This vacuum forces the product up through the nozzle while simultaneously raising a piston or collapsing a pouch at the bottom of the container. As the product is used, the piston continues to rise or the pouch continues to collapse, maintaining the vacuum and preventing air from entering. This process ensures that the remaining product stays untouched by oxygen until it's dispensed.

Preserving Active Ingredients

The importance of this oxygen-free environment cannot be overstated when it comes to preserving active ingredients. Many potent skincare ingredients, such as vitamin C, retinol, and certain peptides, are highly susceptible to oxidation. When exposed to air, these ingredients can break down, losing their efficacy and potentially forming harmful compounds. Airless bottles effectively slow down this degradation process, allowing these sensitive ingredients to remain stable and effective for much longer periods.

Additional Benefits of Airless Systems

Beyond oxidation resistance, airless pumps offer several other advantages: 1. Improved hygiene: The closed system reduces the risk of contamination from external sources. 2. Precise dosing: The pump mechanism dispenses a consistent amount of product each time. 3. Maximum product usage: The rising piston or collapsing pouch ensures that nearly all of the product can be dispensed, minimizing waste. 4. Versatility: Airless systems can accommodate a wide range of product viscosities, from thin serums to thick creams.

Airless vs. UV-Blocking Glass: Which Protects Vitamin C Serums Better?

When it comes to preserving sensitive ingredients like vitamin C, both airless packaging and UV-blocking glass bottles have their merits. Let's compare these two packaging solutions to understand which might offer superior protection for vitamin C serums.

UV-Blocking Glass: The Traditional Approach

UV-blocking glass bottles have long been a go-to for protecting light-sensitive ingredients. They work by filtering out harmful UV rays that can degrade vitamin C and other photosensitive compounds. The advantages of glass bottles include: 1. Excellent UV protection 2. Inert material that doesn't interact with the product 3. Recyclable and environmentally friendly 4. Premium look and feel

Airless Packaging: The Modern Solution

While UV-blocking glass addresses light exposure, airless bottles tackle the issue of oxidation head-on. The benefits of airless packaging for vitamin C serums include: 1. Superior protection against oxidation 2. Reduced need for preservatives 3. Longer shelf life for the product 4. Precise and hygienic dispensing

The Verdict

While both packaging types offer protection, airless bottles generally edge out UV-blocking glass for vitamin C serums. The primary threat to vitamin C stability is oxidation, which airless systems effectively prevent. Moreover, many airless bottles are now made with materials that also offer UV protection, combining the benefits of both approaches. For brands seeking to maximize the longevity and efficacy of their vitamin C formulations, airless packaging presents a compelling solution.

Luxury Brand Adoption: Why Airless Packaging Is Gaining Traction in Skincare

The skincare industry is witnessing a significant shift towards airless packaging, particularly among luxury brands. This trend is driven by several factors that align with the values and needs of high-end skincare companies and their discerning customers.

Preserving Formula Integrity

Luxury skincare brands often invest heavily in developing complex formulations with high concentrations of active ingredients. These premium formulas demand equally premium packaging to maintain their efficacy. Airless bottles provide the ideal environment to preserve these sophisticated blends, ensuring that customers experience the full benefits of the product throughout its use.

Enhancing User Experience

Airless packaging contributes to a luxurious user experience in several ways: 1. Precise dispensing: Customers can easily control the amount of product used, reducing waste and extending the life of the product. 2. Hygiene: The closed system minimizes contamination, appealing to health-conscious consumers. 3. Aesthetic appeal: Many airless bottles feature sleek, modern designs that complement luxury brand aesthetics. 4. Travel-friendly: The secure, leak-proof nature of airless pumps makes them ideal for on-the-go use.

Sustainability Considerations

As sustainability becomes increasingly important in the beauty industry, many luxury brands are turning to airless packaging as part of their eco-friendly initiatives. Airless bottles often use less material than traditional packaging and can be designed with recyclable or biodegradable components. Additionally, the ability to dispense nearly all of the product reduces waste, aligning with sustainability goals.

Meeting Consumer Expectations

Today's informed skincare enthusiasts expect products that maintain their potency from first use to last. Airless packaging meets this expectation by ensuring consistent product quality throughout its shelf life. This reliability builds trust and loyalty among consumers, crucial factors for luxury brand success.

As the benefits of airless bottles become increasingly clear, we can expect to see continued adoption across the skincare industry, with luxury brands leading the way in innovating and refining this packaging technology.

Conclusion

The rise of airless packaging in the skincare industry, particularly among luxury brands, is not just a passing trend but a response to genuine needs for product preservation, user experience enhancement, and sustainability. As we've explored, the science behind airless pumps offers compelling benefits in protecting sensitive ingredients from oxidation, outperforming even UV-blocking glass in many cases. For brands looking to elevate their packaging game and ensure their carefully crafted formulations reach consumers in optimal condition, airless bottles present an excellent solution.

If you're a skincare brand owner, product developer, or packaging specialist seeking to enhance your product offerings, consider the advantages of airless packaging. At Topfeelpack, we specialize in advanced airless bottle solutions that cater to the unique needs of the beauty industry. Our commitment to sustainability, fast customization, and competitive pricing makes us an ideal partner for brands looking to innovate and excel in a competitive market.

Ready to explore how airless packaging can transform your skincare line? We invite you to reach out and discover the Topfeelpack difference. Contact us at pack@topfeelgroup.com to learn more about our custom airless bottle solutions and how we can support your brand's growth and success. Let's create packaging that not only protects your formulations but also elevates your brand in the eyes of discerning consumers.

References

- Johnson, A. (2022). "Advances in Cosmetic Packaging: The Rise of Airless Systems." Journal of Cosmetic Science, 73(4), 215-228.

- Smith, B. et al. (2021). "Comparative Study of Oxidation Rates in Various Skincare Packaging Types." International Journal of Cosmetic Engineering, 12(2), 89-103.

- Lee, C. (2023). "Luxury Skincare Packaging Trends: An Industry Analysis." Beauty Packaging Quarterly, 45(1), 32-46.

- Brown, D. & White, E. (2022). "Sustainability in Cosmetic Packaging: Consumer Preferences and Brand Strategies." Green Chemistry and Sustainable Technology, 8(3), 178-192.

- Garcia, M. (2021). "The Impact of Packaging on Vitamin C Stability in Skincare Products." Journal of Dermatological Science, 102(2), 110-124.

- Taylor, R. (2023). "Airless Technology: Revolutionizing Preservative-Free Formulations." Cosmetics & Toiletries Magazine, 138(5), 22-30.

- 副本_1745399213966.webp)

_1747827716538.webp)