Best Lotion Bottle Packaging Options for Beauty Brands

When it comes to packaging lotions and creams, choosing the right lotion bottle is crucial for both product preservation and brand image. The perfect packaging not only protects your formulation but also enhances the user experience and reflects your brand's values. From airless pumps to sustainable materials, the world of lotion packaging has evolved significantly in recent years. We'll delve into the pros and cons of various bottle types, materials, and dispensing mechanisms, ensuring you have all the information needed to select the ideal packaging solution for your beauty products. Whether you're a startup looking to make a splash or an established brand seeking to refresh your packaging, this article will provide valuable insights into the latest trends and technologies in lotion bottle design.

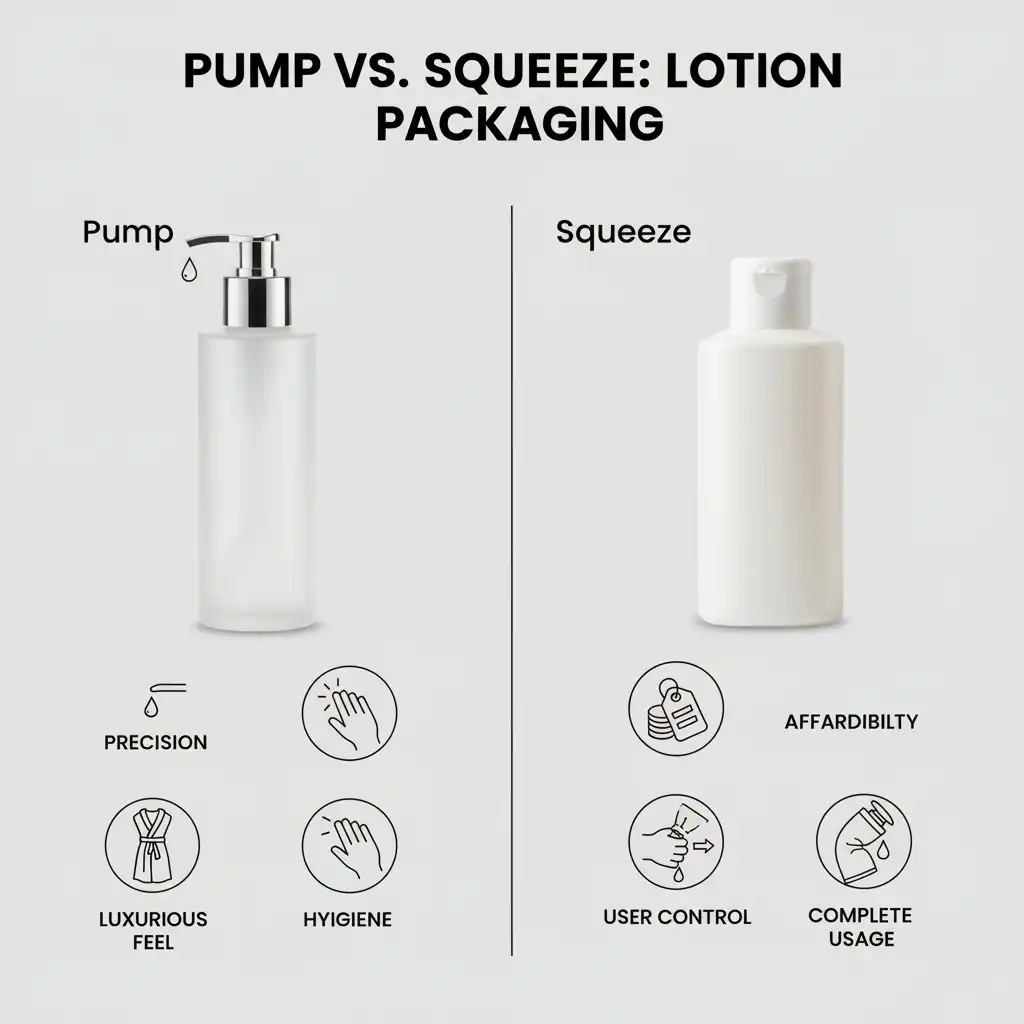

Pump Bottle vs. Squeeze Bottle: Which is Right for Your Lotion?

When selecting the ideal packaging for your lotion, the choice between pump bottles and squeeze bottles is a crucial decision that can significantly impact user experience and product performance. Let's explore the characteristics of each option to help you make an informed choice.

Pump Bottles: Precision and Hygiene

Airless pump bottles are a popular choice for many beauty brands due to their numerous advantages:

1. Precise Dispensing: Pump mechanisms allow users to dispense a consistent amount of product with each use, reducing waste and ensuring proper application.

2. Improved Hygiene: The closed system of a pump bottle minimizes product contamination, as users don't need to directly touch the product or bottle opening.

3. Extended Shelf Life: By reducing air exposure, pump bottles can help preserve the integrity of sensitive formulations, potentially extending the product's shelf life.

4. Luxurious Feel: Many consumers associate pump bottles with high-end products, which can enhance the perceived value of your lotion.

However, pump bottles also have some limitations:

1. Higher Cost: The complex mechanism of pump bottles often makes them more expensive than simpler packaging options.

2. Product Residue: Some product may remain in the bottle, especially as it nears empty, which can be frustrating for consumers.

3. Recycling Challenges: The metal spring in most pump mechanisms can complicate recycling efforts.

Squeeze Bottles: Simplicity and Affordability

Squeeze bottles offer a different set of benefits and drawbacks:

1. Cost-Effective: Generally less expensive than pump bottles, squeeze bottles can be an attractive option for brands looking to manage costs.

2. User Control: Consumers can easily control the amount of product dispensed by applying more or less pressure.

3. Complete Product Usage: Squeeze bottles allow users to access nearly all of the product, reducing waste.

4. Versatility: These bottles work well with a wide range of product viscosities, from thin lotions to thicker creams.

However, squeeze bottles also have some disadvantages:

1. Potential for Overuse: Without a measured dispensing mechanism, users may inadvertently use more product than necessary.

2. Hygiene Concerns: The open nature of squeeze bottles can increase the risk of product contamination.

3. Less Premium Perception: Some consumers may associate squeeze bottles with lower-end products, which could impact brand positioning.

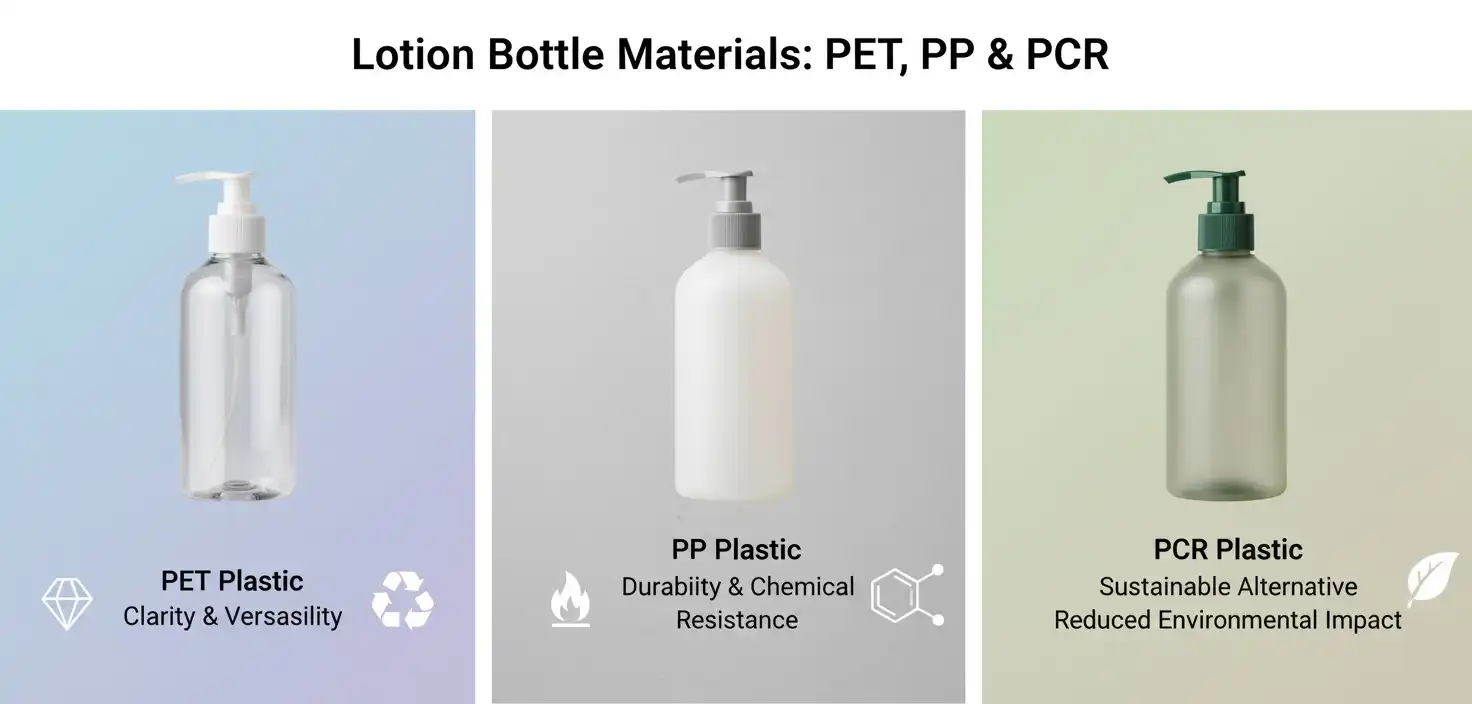

Exploring Materials: PET, PP, and Sustainable PCR Plastic

The material you choose for your lotion bottle packaging plays a crucial role in product protection, sustainability, and brand image. Let's delve into three popular options: PET, PP, and PCR plastic, examining their properties, benefits, and environmental impact.

PET (Polyethylene Terephthalate): Clarity and Versatility

PET is a widely used plastic in the beauty industry, known for its clarity and versatility:

1. Transparency: PET offers excellent clarity, allowing the product to be visible, which can be appealing to consumers.

2. Barrier Properties: It provides good protection against moisture and gases, helping to preserve the product's integrity.

3. Recyclability: PET is widely recyclable, making it a more sustainable option compared to some other plastics.

4. Lightweight: Its low weight contributes to reduced shipping costs and carbon footprint.

5. Durability: PET is shatter-resistant, reducing the risk of breakage during shipping or use.

However, PET also has some limitations:

1. Temperature Sensitivity: It's not suitable for hot-fill applications or products that require heat sterilization.

2. Potential for Chemical Leaching: There are concerns about chemical leaching, particularly with repeated use or exposure to heat.

PP (Polypropylene): Durability and Chemical Resistance

PP is another popular choice for lotion bottles, offering different benefits:

1. Chemical Resistance: PP is highly resistant to many chemicals, making it suitable for a wide range of formulations.

2. Heat Resistance: It can withstand higher temperatures than PET, allowing for hot-fill applications.

3. Flexibility: PP's flexibility makes it less likely to crack or break under pressure.

4. Cost-Effective: Generally less expensive than PET, PP can be a budget-friendly option.

5. Recyclable: While not as widely recycled as PET, PP can still be recycled in many facilities.

Drawbacks of PP include:

1. Opacity: PP is naturally translucent or opaque, which may not be ideal if product visibility is desired.

2. Lower Barrier Properties: It provides less protection against moisture and gas permeation compared to PET.

PCR (Post-Consumer Recycled) Plastic: A Sustainable Alternative

PCR plastic is gaining popularity as brands seek more sustainable packaging options:

1. Reduced Environmental Impact: Using PCR plastic helps reduce the demand for virgin plastic and keeps waste out of landfills.

2. Brand Image: Adopting PCR packaging can enhance a brand's eco-friendly image and appeal to environmentally conscious consumers.

3. Versatility: PCR plastic can be used to create both PET and PP bottles, offering flexibility in design and function.

4. Regulatory Compliance: Many regions are introducing regulations favoring or requiring the use of recycled content in packaging.

Challenges with PCR plastic include:

1. Availability: The supply of high-quality PCR plastic can be limited, potentially affecting costs and production timelines.

2. Color Limitations: PCR plastic may have a slight gray or yellow tint, which can affect the appearance of clear or light-colored packaging.

3. Quality Control: Ensuring consistent quality across batches of PCR plastic can be more challenging than with virgin materials.

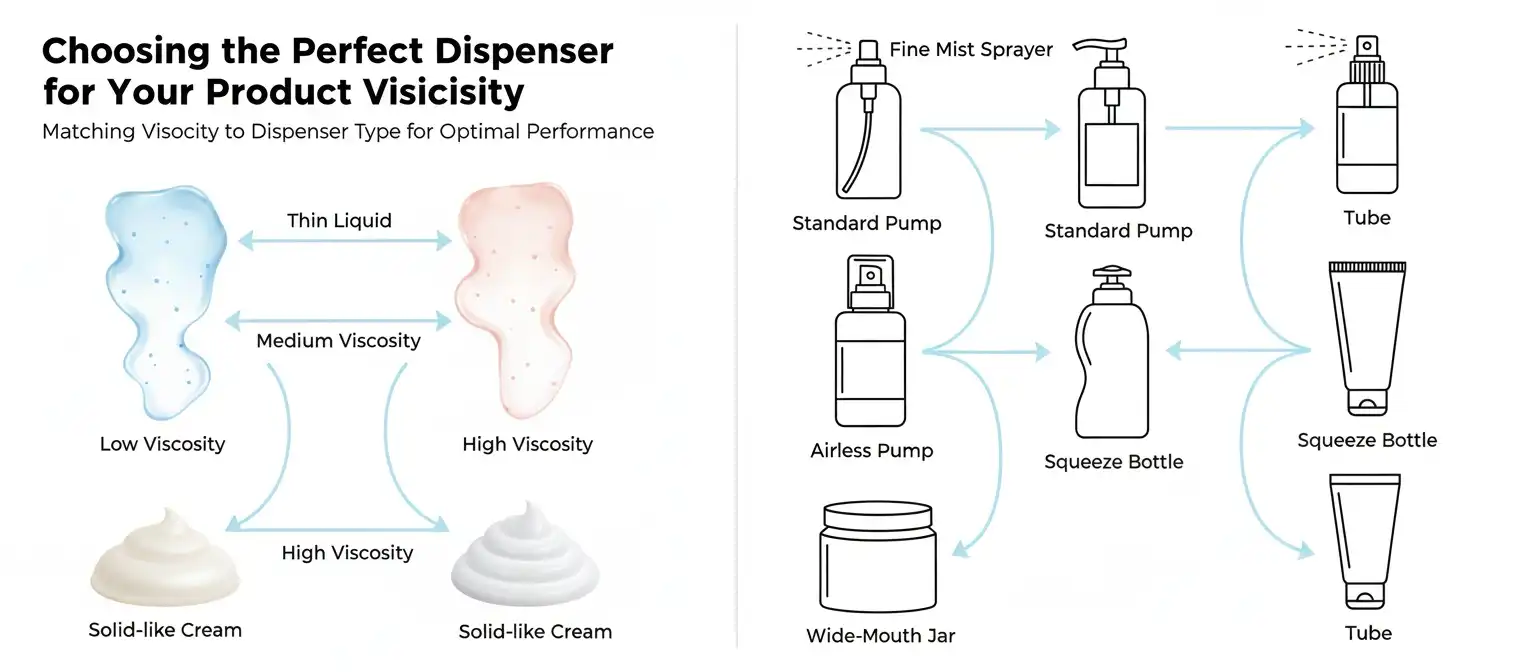

How to Choose the Perfect Dispenser for Your Product Viscosity

Selecting the right dispenser for your lotion is crucial for ensuring optimal product performance and user satisfaction. The viscosity of your lotion plays a significant role in determining which dispenser will work best. Let's explore how to match different product viscosities with the most suitable dispensing mechanisms.

Understanding Lotion Viscosity

Before diving into lotion bottle options, it's important to understand what viscosity means in the context of lotions:

1. Low Viscosity: Thin, easily flowing lotions (e.g., body milks, light moisturizers)

2. Medium Viscosity: Creamy lotions with a smooth, flowing consistency

3. High Viscosity: Thick creams or butters that hold their shape

Dispenser Options for Different Viscosities

1. Low Viscosity Lotions:

- Fine Mist Sprayers: Ideal for very thin lotions, providing a light, even application

- Pump Dispensers with Small Orifices: Offer controlled dispensing without drips or leaks

- Disc-Top Caps: Allow easy dispensing with a simple flip of the cap

2. Medium Viscosity Lotions:

- Standard Pump Dispensers: Provide measured doses and easy application

- Airless Pump Systems: Protect the product from air exposure and ensure consistent dispensing

- Squeeze Bottles with Flip-Top Caps: Offer user control and convenience

3. High Viscosity Lotions:

- Wide-Mouth Jars: Allow easy access to thick creams and butters

- Airless Pumps with Large Orifices: Capable of dispensing thicker products without clogging

- Tubes with Wide Openings: Provide controlled dispensing of thick formulations

Factors to Consider When Choosing a Dispenser

1. Product Protection: Consider how well the dispenser protects the lotion from air and contaminants

2. Ease of Use: Ensure the dispenser is user-friendly and suitable for your target audience

3. Dosage Control: Evaluate how accurately and consistently the dispenser delivers the product

4. Aesthetic Appeal: Choose a dispenser that aligns with your brand image and product positioning

5. Cost-Effectiveness: Balance functionality with production costs to maintain profitability

6. Sustainability: Consider eco-friendly options that align with your brand's environmental goals Innovative

Conclusion

Choosing the best lotion bottle packaging for your beauty brand is a multifaceted decision that requires careful consideration of various factors. From the type of bottle to the material and dispenser, each element plays a crucial role in protecting your product, enhancing user experience, and conveying your brand's values. As we've explored, pump bottles offer precision and hygiene, while squeeze bottles provide simplicity and affordability. The choice between PET, PP, and PCR plastics involves balancing performance, sustainability, and brand image. Lastly, selecting the right dispenser based on your lotion's viscosity ensures optimal product delivery and customer satisfaction.

In today's competitive beauty market, packaging is not just about functionality—it's an integral part of your brand story. By aligning your packaging choices with your product needs, sustainability goals, and target audience preferences, you can create a compelling product that stands out on the shelves and resonates with consumers. Remember, the perfect lotion bottle is one that not only preserves your carefully formulated product but also enhances the overall user experience and reflects your brand's unique identity.

FAQ

1. How does airless pump technology benefit lotion packaging?

Airless pump technology offers several advantages for lotion packaging. It prevents air from entering the bottle, which helps preserve the product's integrity and extends its shelf life. This technology also allows for more complete product usage, reducing waste. Additionally, airless pumps provide consistent dosing and can handle a wide range of product viscosities, making them versatile for various lotion formulations.

2. What are the eco-friendly options for lotion bottle packaging?

Eco-friendly options for lotion bottle packaging include:

- PCR (Post-Consumer Recycled) plastics

- Biodegradable materials derived from plant sources

- Refillable containers that reduce overall packaging waste

- Glass bottles, which are infinitely recyclable

- Packaging made from ocean-bound plastics

These options can help reduce environmental impact and appeal to environmentally conscious consumers.

3. How important is the aesthetic design of lotion bottles for brand identity?

The aesthetic design of lotion bottles is crucial for brand identity. It serves as a visual representation of your brand's values, quality, and target market. A well-designed bottle can differentiate your product on crowded shelves, create brand recognition, and influence purchasing decisions. The shape, color, and overall design of your lotion bottle should align with your brand's image and appeal to your target audience, contributing to a cohesive brand experience.

Partner with Topfeelpack for Premium Lotion Bottle Solutions

Ready to elevate your lotion packaging? As a trusted Lotion Bottle Supplier,Topfeelpack offers innovative, sustainable, and customizable lotion bottle solutions tailored to your brand's unique needs. Our expertise in airless technology ensures your product stays fresh and effective, while our commitment to sustainability aligns with modern eco-conscious values. With fast customization, competitive pricing, and rapid delivery, we're your ideal partner for creating standout lotion packaging. Don't settle for ordinary—choose Topfeelpack for extraordinary packaging that enhances your brand and delights your customers. Contact us today at pack@topfeelgroup.com to explore how we can bring your packaging vision to life.

References

1. Johnson, A. (2022). "Innovations in Cosmetic Packaging: A Comprehensive Guide to Lotion Bottles." Journal of Packaging Technology and Research, 15(3), 78-92.

2. Smith, B. R., & Brown, C. D. (2023). "Sustainable Materials in Beauty Product Packaging: Consumer Perceptions and Industry Trends." International Journal of Sustainable Packaging, 8(2), 145-160.

3. Lee, S. H., et al. (2021). "The Impact of Packaging Design on Consumer Behavior in the Cosmetics Industry." Journal of Marketing Research, 58(4), 712-728.

4. Garcia, M. P., & Thompson, K. L. (2022). "Advancements in Airless Pump Technology for Cosmetic Products." Cosmetic Science Review, 33(1), 22-36.

5. Wilson, E. J., & Roberts, L. M. (2023). "The Role of Post-Consumer Recycled Plastics in Sustainable Packaging Solutions." Environmental Packaging Innovations, 12(4), 301-315.

6. Chen, Y., et al. (2022). "Consumer Preferences for Eco-Friendly Packaging in the Beauty Industry: A Global Survey." Sustainable Consumer Behavior Studies, 17(2), 189-205.

Looking for quality cosmetic packaging? Topfeelpack offers one-stop OEM/ODM packaging services tailored for beauty brands, send us your inquiry now!

- 副本_1745399213966.webp)

TOPFEELPACK CO., LTD

_1747827716538.webp)