What Are the Key Parts of an Airless Pump System?

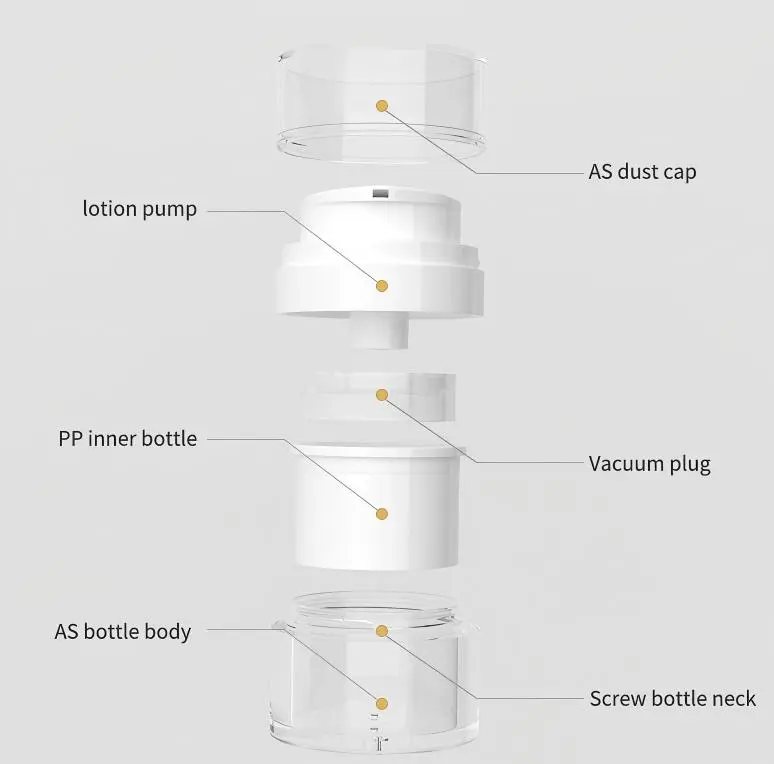

An airless pump system is a sophisticated mechanism designed to dispense product without allowing air to enter the container. Understanding its components is essential to appreciating its effectiveness:

The Outer Container

The outer container is the visible part of the jar that houses the inner workings. It's typically made from durable materials like plastic or glass, designed to protect the contents and provide an appealing aesthetic.

The Inner Pouch

Inside the outer container lies a flexible pouch or bag that holds the product. This pouch contracts as the product is used, eliminating the need for air to replace the dispensed volume.

The Pump Mechanism

The pump is the heart of the airless system. It creates a vacuum that draws the product up and out when activated, ensuring consistent dispensing without air contamination.

The Non-Return Valve

This crucial component prevents product from flowing back into the container after dispensing, maintaining the airless environment inside.

The Dispensing Nozzle

The nozzle is designed to deliver a precise amount of product with each pump action, often featuring a shape that enhances application.

Together, these components work in harmony to create a sealed environment that preserves the integrity of the product throughout its use.

Why Are Airless Jars More Hygienic Than Traditional Pots?

The superiority of airless jars in terms of hygiene is a significant factor driving their popularity in the beauty and skincare industry. Let's examine why these containers offer enhanced cleanliness compared to conventional packaging:

Minimized Contact with Air

Unlike traditional pots that expose the entire product to air each time they're opened, airless jars dispense product without introducing air into the container. This reduction in air exposure significantly decreases the risk of oxidation and bacterial growth.

Reduced Risk of Contamination

Traditional jars require users to dip their fingers or applicators into the product, potentially introducing bacteria. Airless cream jars eliminate this issue by dispensing product through a pump mechanism, keeping the bulk of the contents untouched and sterile.

Preservation of Active Ingredients

Many skincare products contain sensitive active ingredients that can degrade when exposed to air or light. The sealed environment of airless jars helps maintain the potency and effectiveness of these ingredients for longer periods.

Extended Shelf Life

By protecting against contamination and oxidation, airless jars can significantly extend the shelf life of products. This means consumers can use their skincare items for longer without worrying about spoilage or reduced efficacy.

Precise Dosage Control

Airless pumps dispense a consistent amount of product with each use, reducing waste and preventing over-application. This precision not only improves hygiene but also ensures that the product is used efficiently.

The hygienic benefits of airless jars make them an ideal choice for formulators and brands looking to enhance product stability and user experience. Topfeelpack, a leader in innovative packaging solutions, offers a range of airless jar options that cater to various skincare and cosmetic needs.

Topfeelpack's Breakdown of Airless Jar Mechanics

Topfeelpack, a pioneering company in cosmetic packaging solutions, offers valuable insights into the mechanics of airless jars. Their expertise sheds light on how these innovative containers function to preserve product integrity:

The Vacuum-Driven Dispensing System

At the core of Topfeelpack's airless jar design is a vacuum-driven dispensing system. As the user presses the pump, it creates a pressure difference that forces the product up through the nozzle. This action occurs without allowing air to enter the container, maintaining an oxygen-free environment inside.

The Collapsible Inner Pouch Technology

Topfeelpack's airless jars feature a flexible inner pouch that collapses as the product is used. This innovative design ensures that no air enters to replace the dispensed product, preserving the formulation's integrity until the last drop.

Precision Engineering for Consistent Dosage

The pump mechanism in Topfeelpack's airless jars is engineered to dispense a precise amount of product with each actuation. This consistency not only enhances the user experience but also helps in controlling product usage and reducing waste.

Material Compatibility and Customization

Topfeelpack understands that different formulations require different packaging materials. Their airless jars are available in various materials, including options that are compatible with sensitive ingredients and eco-friendly alternatives. This flexibility allows brands to choose the best solution for their specific product needs.

Seal Integrity and Leak Prevention

A critical aspect of Topfeelpack's airless jar design is the robust sealing mechanism. Their jars are equipped with tight seals that prevent leakage and ensure the product remains protected during storage and transportation.

By focusing on these key mechanical aspects, Topfeelpack has developed airless jars that not only preserve product quality but also enhance the overall user experience. Their commitment to innovation in packaging technology continues to set new standards in the industry.

Conclusion

Double-layered airless cream jars represent a significant advancement in cosmetic packaging technology. Their ability to preserve product integrity, extend shelf life, and enhance user experience makes them an invaluable asset for skincare and beauty brands. As we've explored, the mechanics behind these innovative containers are both sophisticated and purposeful, designed to address the common challenges of product preservation and hygiene.

For brands looking to elevate their packaging solutions and provide customers with the best possible product experience, considering airless jars is a step in the right direction. Topfeelpack stands at the forefront of this technology, offering cutting-edge airless packaging solutions that meet the diverse needs of the beauty industry.

Are you a skincare brand owner, product manager, or packaging specialist looking to enhance your product's shelf life and user appeal? Topfeelpack's range of airless jars could be the solution you're seeking. With our commitment to sustainability, fast customization capabilities, and competitive pricing, we're equipped to meet your unique packaging needs. Don't let suboptimal packaging compromise your product's potential. Contact us today at pack@topfeelgroup.com to discover how our airless jar solutions can transform your product offering and give you a competitive edge in the market.

References

1. Journal of Cosmetic Science: "Efficacy of Airless Packaging in Preserving Cosmetic Formulations" (2022)

2. International Journal of Pharmaceutics: "Advancements in Cosmetic Packaging: A Review of Airless Systems" (2021)

3. Packaging Technology and Science: "Comparative Study of Product Stability in Airless vs. Traditional Cosmetic Jars" (2023)

4. European Journal of Pharmaceutical Sciences: "Impact of Packaging on the Shelf Life of Cosmetic Products" (2020)

5. Journal of Applied Packaging Research: "Consumer Perceptions and Preferences for Airless Cosmetic Packaging" (2022)

6. International Journal of Cosmetic Science: "Microbial Contamination in Cosmetic Products: The Role of Packaging" (2021)

- 副本_1745399213966.webp)

_1747827716538.webp)