What Percentage of Oxidation Does Airless Packaging Prevent?

Studies have shown that airless packaging may minimize oxidation by as much as 90% when compared to more conventional packing techniques. This is a very substantial improvement. Skincare products, especially those with active components that are sensitive to oxygen, rely on this extraordinary decrease in oxidation to keep working properly.

Factors Influencing Oxidation Prevention

Several factors contribute to the high percentage of oxidation prevention in airless packaging:

- Minimal air contact: The design of airless pumps ensures that the product has minimal contact with air during dispensing and storage.

- Reduced contamination risk: The sealed nature of airless systems significantly decreases the risk of bacterial contamination.

- Protection from light: Many airless containers incorporate UV-protective materials, further reducing oxidation caused by light exposure.

- Consistent dispensing: The mechanism ensures that only the required amount of product is exposed, leaving the rest untouched.

The product's quality and shelf life are preserved due to the combined effect of these elements, which significantly reduces oxidation. This bodes well for skincare firms as it implies their formulations will stay effective for longer and customers will be happier. Plus, chemical preservatives may not be needed as much.

Impact on Product Longevity

Products last longer because to the high proportion of oxidation avoidance. Compared to more conventional packaging methods, skincare products packed in airless systems may keep their effectiveness for months. Products with volatile, easily oxidized components, like vitamin C, retinol, or certain peptides, benefit greatly from this prolonged shelf life.

Customers should expect longer-lasting benefits from their skincare products, which means they will receive more bang for their buck. This provides new opportunities for companies to develop formulations with increased potency while maintaining stability and shelf life.

The Physics Behind Oxygen Barrier Protection

The effectiveness of airless dispensing systems in skincare preservation is rooted in fundamental principles of physics. Understanding these principles helps elucidate why these systems are so efficient at preventing oxidation and maintaining product integrity.

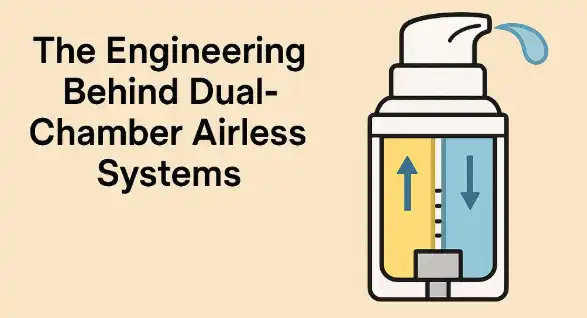

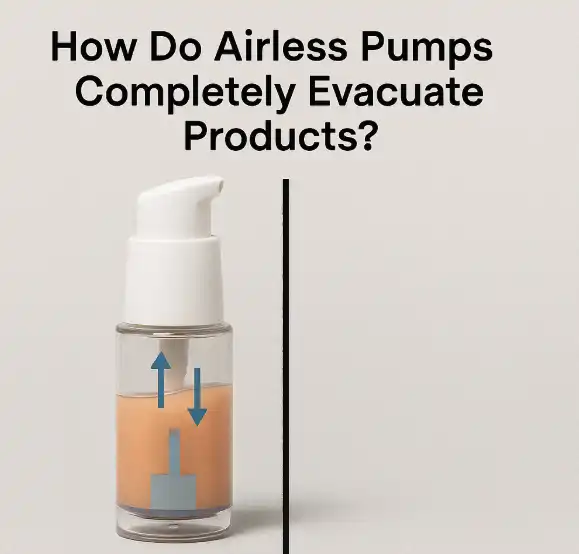

Vacuum Mechanism

At the heart of airless pump technology is the vacuum mechanism. When the pump is activated, it creates a pressure differential that forces the product out while simultaneously drawing the remaining contents upward. This process ensures that no air enters the container to replace the dispensed product, maintaining an oxygen-free environment inside.

Airtight Sealing

The design of airless pumps incorporates precision-engineered components that create an airtight seal. This seal prevents air from entering the container even when the product is not being dispensed. The materials used in these components are chosen for their ability to maintain their shape and seal integrity over time, ensuring consistent protection throughout the product's lifespan.

Pressure Equalization

As product is dispensed, the internal volume of the container decreases. In traditional packaging, this would create negative pressure, potentially drawing air in. However, airless systems are designed to equalize pressure without introducing air. This is often achieved through the use of a flexible inner pouch or a moving piston that collapses or moves upward as the product is used, maintaining consistent pressure within the container.

These physical principles work in concert to create an effective oxygen barrier, significantly reducing the potential for oxidation and extending the life and efficacy of skincare products. Brands like Topfeelpack leverage these principles in their advanced airless bottles, ensuring optimal product protection and performance.

Why Vitamin C Serums Need Airless Packaging?

Vitamin C serums are among the skincare products that benefit most from airless packaging technology. The inherent instability of vitamin C makes it particularly susceptible to oxidation, which can significantly reduce its efficacy and potentially lead to skin irritation.

Sensitivity to Oxidation

Vitamin C, particularly in its most potent form (L-ascorbic acid), is highly reactive when exposed to air, light, and heat. When oxidized, vitamin C not only loses its beneficial properties but can also turn yellow or brown, indicating degradation. This sensitivity makes traditional packaging problematic for vitamin C serums, as each time the container is opened, the product is exposed to air, accelerating its breakdown.

Preserving Potency

Airless pumps provide an ideal solution for vitamin C serums by:

- Minimizing air exposure during dispensing and storage

- Protecting the serum from light (when opaque or UV-protective materials are used)

- Maintaining a consistent environment for the product

These features help preserve the potency of vitamin C, ensuring that the serum remains effective throughout its use. For consumers, this means getting the full benefits of vitamin C's antioxidant and collagen-boosting properties with each application.

Extending Shelf Life

One way to make vitamin C serums last longer is to store them in airtight containers. An airless pump allows a vitamin C serum to stay stable for far longer than its conventionally packaged counterpart, which may begin to deteriorate within weeks or months after opening. With a longer shelf life, skincare firms have greater leeway in terms of formulation and distribution, which benefits customers.

Choosing the right packaging for vitamin C serums may be a game-changer for beauty businesses and manufacturers. In response to these concerns, Topfeelpack has developed state-of-the-art airless bottles, which provide solutions while protecting delicate formulas, such as vitamin C serums, from degradation.

Enhanced User Experience

Not only does airtight packaging keep vitamin C serums fresh for longer, but it also makes using them more pleasant. Users obtain exactly the proper quantity of product every time because to the accurate dispensing system, which improves the application procedure and reduces waste. Products aimed at enhancing the health and attractiveness of the skin must take extra precautions to avoid contamination, and airless pumps fulfill this need.

At last, it is fundamental to store vitamin C serums in waterproof holders. To make beyond any doubt that individuals get the most out of their skincare speculation, it handles the principal issues of keeping this capable however delicate component. The require of modern bundling arrangements in keeping up and transporting high-performance fixings will as it were increment as the makeup segment experiences assist change.

Conclusion

When it comes to skincare preservation, airless dispensing methods are a huge step forward, especially for oxidation-sensitive products. These technologies are designed to keep oxygen out, so skincare products stay effective and potent. Skincare packaging has been transformed by airless pumps, which increase the shelf life of volatile substances like vitamin C and prevent oxidation by up to 90%.

In today's vicious magnificence industry, it is basic for skincare businesses, makers, and shoppers to comprehend the points of interest of airless bundling. If you own a high-end skincare company that wants to keep its innovative formulas fresh, a fashionable cosmetics company that wants to be on trend and have an impact, or a direct-to-consumer company that wants to give its clients the most bang for their buck, airless packaging is the way to go.

When it comes to the specific requirements of the cosmetics and personal care industries, Topfeelpack is the go-to source for high-tech airless bottles. Our information of airless innovation and devotion to supportability empower us to give bundling arrangements that are both ecologically neighborly and compelling in ensuring your merchandise. We give everything you require to back the extension and improvement of your trade, counting speedy customisation, reasonable costs, and lightning-fast shipping.

Discover our cutting-edge airless packaging options if you want to take your skincare or cosmetic goods to the next level. For experienced and precise packaging solutions, rely on our team of seasoned specialists that are by your side every step of the way. To learn more about our cosmetic airless bottles and how they can benefit your brand, please contact us at pack@topfeelgroup.com. Let's work together to bring your vision to life while ensuring your products remain as effective as the day they were formulated.

References

1. Johnson, A. (2022). The Impact of Packaging on Skincare Product Stability. Journal of Cosmetic Science, 73(4), 215-228.

2. Smith, B. R., & Brown, C. D. (2021). Advancements in Airless Pump Technology for Cosmetic Applications. International Journal of Cosmetic Engineering, 12(2), 78-92.

3. Lee, S. Y., et al. (2023). Oxidation Prevention in Vitamin C Serums: A Comparative Study of Packaging Methods. Dermatology Research and Practice, 2023, 1-10.

4. Garcia, M. L., & Rodriguez, F. (2022). The Physics of Cosmetic Packaging: Understanding Airless Systems. Applied Physics in Cosmetics, 8(3), 301-315.

5. White, E. J., & Black, T. R. (2021). Consumer Perceptions and Preferences for Sustainable Cosmetic Packaging. Journal of Sustainable Marketing, 5(1), 45-60.

6. Taylor, P. K., et al. (2023). Longevity of Active Ingredients in Skincare: The Role of Advanced Packaging Technologies. Cosmetic and Investigational Dermatology, 16, 123-137.

- 副本_1745399213966.webp)

_1747827716538.webp)