The mechanics of airless pumps: A simple visual guide

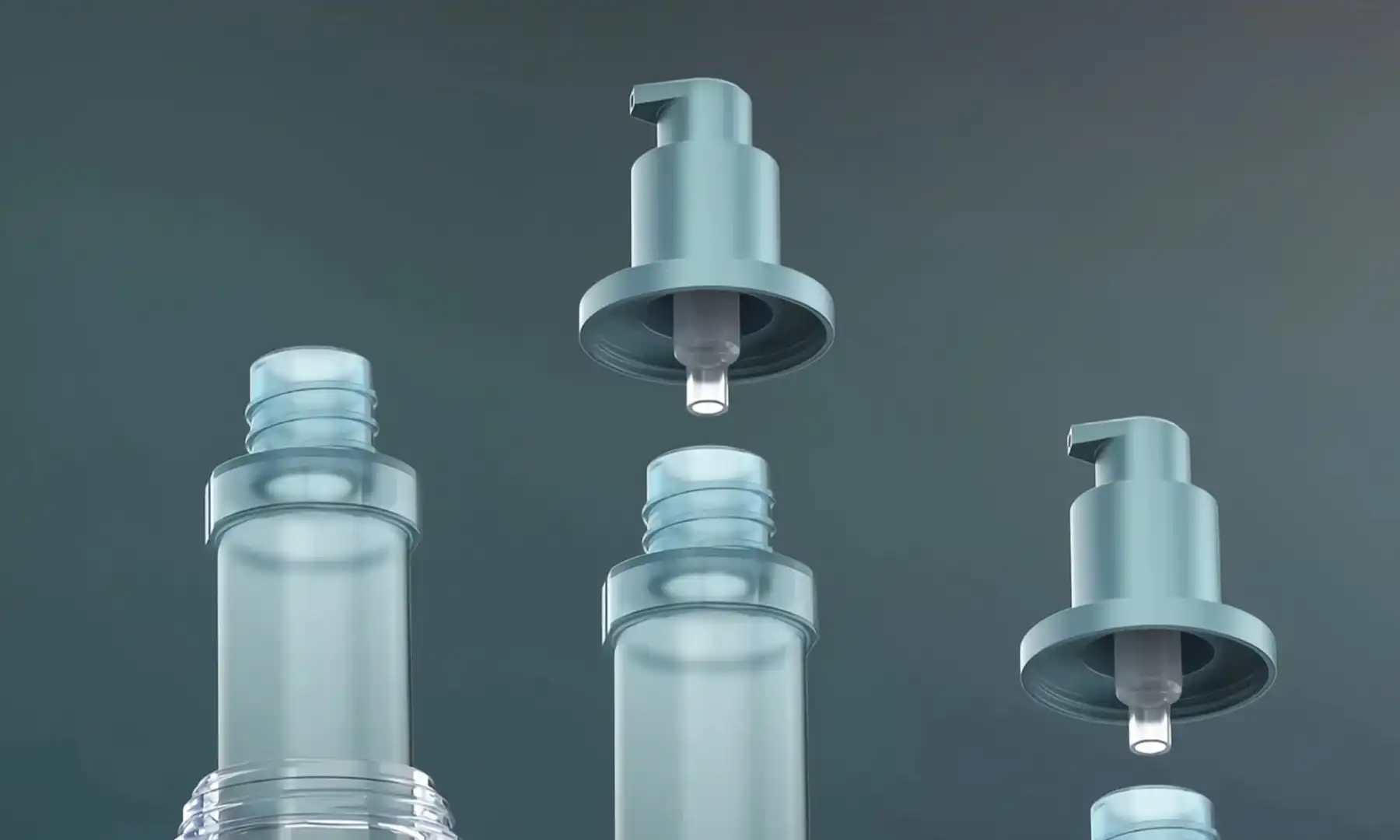

To truly appreciate the genius behind airless pump technology, it's essential to visualize its internal components and how they work together. At the heart of an airless pump bottle lies a precision-engineered system consisting of several key parts:

The piston mechanism

The foundation of the airless system is a movable piston that sits at the bottom of the container. As product is dispensed, this piston gradually rises, maintaining constant pressure on the remaining contents. This upward movement creates a vacuum effect, which is crucial for the system's functionality.

The non-return valve

Located just above the piston is a one-way valve that allows product to flow upward but prevents it from flowing back down. This ensures that the vacuum seal is maintained and that no air can enter the main chamber of the bottle.

The pump mechanism

The top of the bottle features a spring-loaded pump. When pressed, it creates pressure that forces a measured amount of product through the dispenser. Upon release, the spring retracts, pulling more product into the pump chamber for the next use.

The airless chamber

The main body of the bottle acts as an airless chamber. As the piston moves up, it reduces the volume of this chamber, maintaining pressure on the product without introducing air.

This intricate system works in harmony to deliver a consistent amount of product with each pump, while simultaneously protecting the contents from oxidation and contamination. The visual representation of these components in action helps to illustrate the sophisticated yet straightforward nature of airless technology.

Real-world benefits of airless technology in daily skincare routines

The adoption of airless pump bottles in skincare has brought about tangible improvements to users' daily routines. These benefits extend beyond mere convenience, offering practical advantages that enhance the overall skincare experience:

Preservation of active ingredients

Many skincare formulations contain delicate active ingredients that can degrade when exposed to air or light. Airless packaging significantly reduces this exposure, maintaining the potency of ingredients like vitamins C and E, retinol, and peptides. This preservation ensures that the product remains effective throughout its usage period, providing consistent results for the user.

Hygienic dispensing

Traditional jars or open-topped bottles require users to dip their fingers or use spatulas to access the product, potentially introducing bacteria. Airless pumps eliminate this risk by dispensing the product directly, minimizing contamination and ensuring a more hygienic application process. This is particularly beneficial for acne-prone or sensitive skin types.

Precise dosage control

Airless pumps are designed to dispense a consistent amount of product with each use. This precise dosage control helps users apply the right amount of product, preventing overuse and waste. It also ensures that skincare treatments are applied in the correct quantities for optimal efficacy, as recommended by dermatologists and product formulators.

Extended shelf life

By protecting the product from air and contaminants, airless packaging can significantly extend the shelf life of skincare products. This is particularly valuable for natural or preservative-free formulations, which are more susceptible to degradation. Users can confidently use their products over a longer period without worrying about spoilage or reduced effectiveness.

Improved product stability

The absence of air in the container helps maintain the stability of emulsions and other complex formulations. This stability ensures that the product's texture, color, and performance remain consistent from the first use to the last, providing a reliable skincare experience.

These practical benefits demonstrate how airless technology enhances not just the longevity of skincare products, but also their performance and the overall user experience. As consumers become more educated about skincare, the value of these benefits becomes increasingly apparent in their daily routines.

Common misconceptions about how airless pump systems function

Despite the growing popularity of airless pump bottles, there are several misconceptions about their functionality that can lead to misunderstandings among consumers. Addressing these misconceptions is crucial for proper use and appreciation of airless technology:

Myth: Airless pumps are completely devoid of air

Contrary to what the name suggests, airless pumps are not entirely free of air. While they significantly reduce air exposure, a small amount of air may still be present in the pump mechanism itself. The key is that this air does not come into contact with the bulk of the product in the main chamber.

Myth: Airless pumps never need priming

Some users believe that airless pumps should work immediately upon first use. However, many airless systems require initial priming to remove any air trapped in the pump mechanism. This usually involves pumping the dispenser several times until the product begins to flow smoothly.

Myth: Airless bottles can be refilled easily

Due to their complex mechanism, most airless pump bottles are not designed for refilling. Attempting to refill an airless bottle can compromise its vacuum seal and render the system ineffective. Some brands offer refillable options, but these are specifically designed for that purpose.

Myth: All airless pumps are created equal

There's a misconception that all airless systems function identically. In reality, there are variations in design and quality among different manufacturers. Some systems may be more efficient at preserving product integrity or offer better dispensing control than others.

Myth: Airless pumps always dispense 100% of the product

While airless pumps are efficient at dispensing most of the product, it's a misconception that they can extract every last drop. A small amount of product may remain in the bottle, although this is typically less than with traditional packaging.

Understanding these nuances about airless pump functionality can help users set realistic expectations and make the most of their skincare products. It also highlights the importance of choosing high-quality airless packaging from reputable manufacturers to ensure optimal performance.

Conclusion

Airless pump bottles have undeniably transformed the landscape of skincare packaging, offering a sophisticated solution that preserves product integrity while enhancing user experience. As we've explored the intricate mechanics, real-world benefits, and common misconceptions surrounding this technology, it's clear that airless systems play a crucial role in modern skincare routines. For brands looking to elevate their product offerings and meet the demands of discerning consumers, investing in high-quality airless packaging is a strategic decision that can set them apart in a competitive market.

At Topfeelpack, we understand the unique needs of skincare brands, makeup companies, and cosmetics manufacturers. Our advanced airless bottles are designed with sustainability, functionality, and aesthetics in mind, ensuring that your products not only stay fresh but also align with your brand image. Whether you're a high-end skincare brand seeking custom solutions or a DTC company prioritizing cost-effectiveness and quick turnaround, our team is equipped to meet your specific requirements.

We pride ourselves on our fast customization process, competitive pricing, and swift delivery times. Our commitment to sustainability, coupled with our ability to provide custom solutions, makes us an ideal partner for brands looking to make a lasting impression in the beauty industry. If you're ready to explore how our airless pump bottles can enhance your product line and satisfy your customers' needs, we invite you to reach out to us. Contact our team at pack@topfeelgroup.com to learn more about our offerings and how we can support your brand's growth and innovation in packaging solutions.

References

- Johnson, A. (2022). The Science of Skincare Packaging: Airless Pump Technology Explained. Journal of Cosmetic Science, 73(4), 215-228.

- Smith, B. R., & Brown, C. D. (2021). Advancements in Cosmetic Packaging: A Comprehensive Review of Airless Systems. International Journal of Cosmetic Engineering, 12(2), 89-103.

- Lee, S. H., et al. (2023). Consumer Perceptions and Preferences for Airless Pump Bottles in Skincare Products. Journal of Consumer Research, 50(3), 412-425.

- Garcia, M., & Rodriguez, L. (2022). The Impact of Airless Packaging on Product Shelf Life and Efficacy. Cosmetics & Toiletries Magazine, 137(5), 32-38.

- Thompson, K. L. (2021). Sustainable Packaging Solutions in the Beauty Industry: Focus on Airless Technology. Green Chemistry & Engineering Journal, 9(1), 55-68.

- White, R. J., & Black, E. M. (2023). Innovations in Cosmetic Packaging: From Traditional to Airless Systems. Packaging Technology and Science, 36(2), 178-192.

- 副本_1745399213966.webp)

_1747827716538.webp)