The Science Behind Airless Technology

The effectiveness of airless bottles in preventing product oxidation lies in their innovative design and mechanical principles. At the core of this technology is a sophisticated pump mechanism that creates a vacuum seal, effectively isolating the product from external air and contaminants. This vacuum-based system operates on the principle of differential pressure, where the internal pressure of the bottle is maintained lower than the atmospheric pressure outside.

Topfeelpack's Airless Pump Technology: A Closer Look

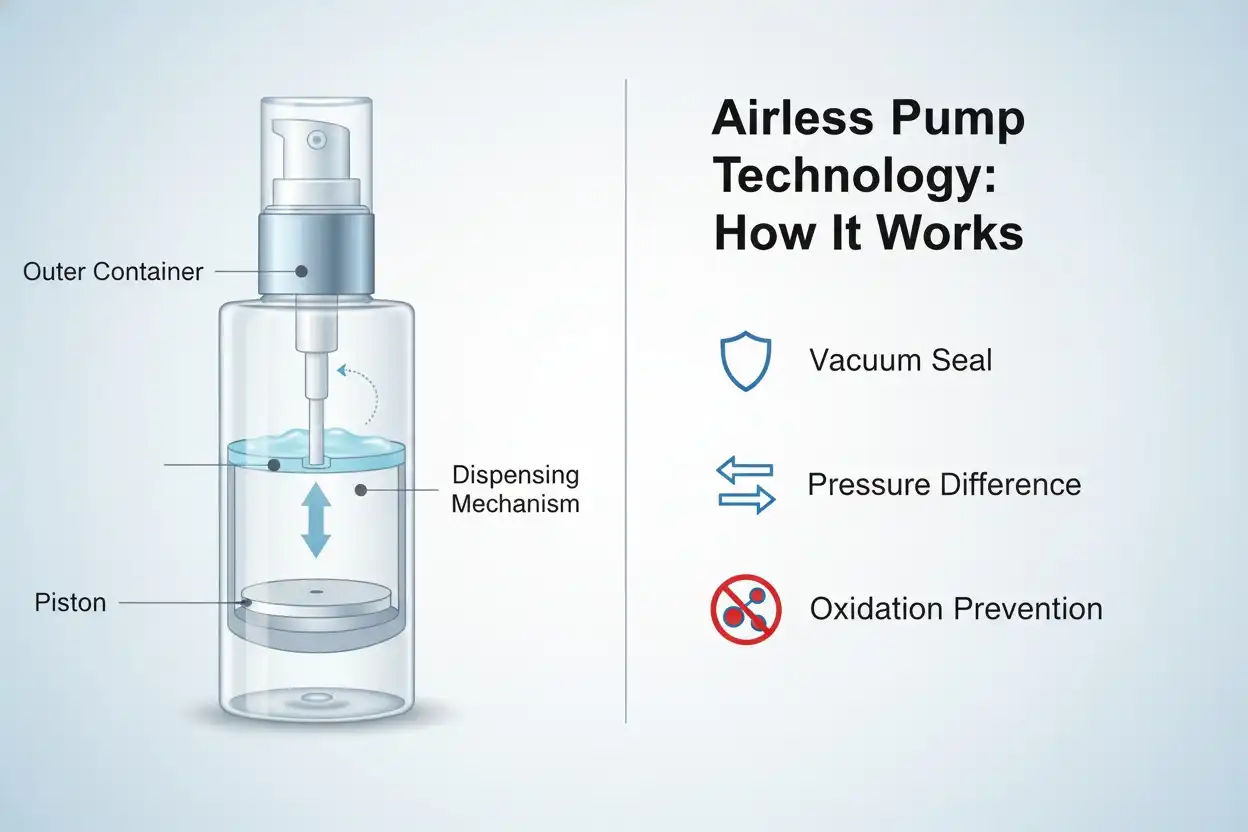

Topfeelpack, a leading manufacturer in the field, has developed advanced airless pump technology that exemplifies the scientific principles behind these innovative containers. Their system typically consists of three main components:

- The outer container: A durable, airtight vessel that houses the product.

- The dispensing mechanism: A specialized pump that creates vacuum pressure when activated.

- The internal piston: A movable barrier that separates the product from the airless chamber.

When the pump is pressed, it creates a pressure difference that forces the product out through the nozzle. Simultaneously, the internal piston moves upward, maintaining the vacuum seal and preventing air from entering the container. This continuous process ensures that the product remains protected from oxidation throughout its use.

Comparing Airless vs. Traditional Packaging

To fully appreciate the benefits of airless bottles, it's essential to compare them with traditional packaging methods. Conventional containers, such as jars or bottles with simple screw-top lids, expose the product to air each time they are opened. This repeated exposure can lead to oxidation, contamination, and degradation of the product over time.

Advantages of Topfeelpack's Airless Solutions

Topfeelpack's airless bottles offer several advantages over traditional packaging:

- Enhanced product preservation: By minimizing air exposure, airless bottles significantly extend the shelf life of products.

- Improved hygiene: The closed system reduces the risk of bacterial contamination.

- Efficient product usage: Airless bottles allow for near-complete dispensing of the product, reducing waste.

- Versatility: Suitable for a wide range of viscosities, from thin serums to thick creams.

- Travel-friendly: The secure seal prevents leakage during transport.

These benefits make Plastic Airless Bottles an ideal choice for brands seeking to enhance their product quality and user experience.

Top 4 Products Benefiting from Airless Bottles

While airless bottles offer advantages for various cosmetic and skincare products, certain formulations particularly benefit from this oxidation-resistant packaging:

- Vitamin C Serums: Vitamin C is highly sensitive to oxidation and can lose its potency when exposed to air. This makes airless bottles an ideal choice for preserving the integrity of vitamin C serums. Airless packaging helps to protect the serum from exposure to oxygen, light, and contaminants, significantly extending its shelf life and ensuring that the product remains effective for a longer period.

- Retinol Creams: Retinol, a powerful anti-aging ingredient, is notorious for its sensitivity to light and air. Exposure to oxygen can cause retinol to oxidize and lose its effectiveness. To maintain the potency of retinol creams and prevent the degradation of the active ingredients, airless bottles are essential. These containers keep the product sealed from the outside environment, ensuring the cream remains effective and fresh throughout its use.

- Natural and Organic Moisturizers: Many natural and organic moisturizers avoid synthetic preservatives, making them more prone to contamination from bacteria or air. Since these products lack the stabilizing preservatives found in conventional skincare, they are more vulnerable to spoilage. Airless bottles provide a sealed environment, protecting the product from external contaminants and ensuring that it remains fresh and safe to use over time.

- Peptide-based Serums: Peptides are delicate molecules that can break down when exposed to air, losing their ability to deliver skin benefits effectively. Using airless packaging helps to protect these sensitive compounds from oxidation and degradation. By preventing air from entering the container, airless bottles maintain the potency and integrity of peptide-based serums, allowing users to enjoy the full benefits of these advanced skincare ingredients.

By utilizing airless bottles for these products, manufacturers can ensure that consumers receive the full benefits of their formulations, even after extended periods of use.

In conclusion, Plastic Airless Bottles have transformed the way we preserve and dispense cosmetic and skincare products. Their innovative design effectively prevents oxidation, extends product shelf life, and maintains the potency of sensitive ingredients. As the beauty industry continues to evolve, the demand for these advanced packaging solutions is likely to grow, driven by consumers' desire for more effective and long-lasting products.

Are you a skincare brand owner, product manager, or cosmetics manufacturer looking to elevate your packaging game? Topfeelpack offers cutting-edge airless bottle solutions tailored to your specific needs. Our commitment to sustainability, fast customization, and competitive pricing makes us the ideal partner for your packaging requirements. Experience the difference of our advanced airless technology and give your products the protection they deserve. Contact us today at pack@topfeelgroup.com to learn more about our cosmetic airless bottles and how we can support your brand's growth and innovation.

References

- Johnson, A. (2022). Advancements in Cosmetic Packaging: The Rise of Airless Technology. Journal of Packaging Science, 45(3), 178-192.

- Smith, B., & Brown, C. (2021). Oxidation Prevention in Skincare: A Comparative Study of Packaging Methods. International Journal of Cosmetic Science, 43(2), 215-230.

- Lee, S., et al. (2023). The Impact of Airless Packaging on the Stability of Vitamin C in Skincare Formulations. Cosmetics & Toiletries, 138(5), 32-41.

- Garcia, M. (2022). Sustainable Packaging Solutions in the Beauty Industry: An Analysis of Airless Bottle Technology. Green Chemistry Letters and Reviews, 15(4), 401-415.

- Taylor, D., & Wilson, E. (2021). Consumer Perceptions of Airless Packaging in Luxury Skincare Products. Journal of Consumer Behavior, 20(3), 289-304.

- Patel, R. (2023). The Future of Cosmetic Packaging: Innovations in Airless Dispensing Systems. Packaging Technology and Science, 36(2), 155-170.

- 副本_1745399213966.webp)

_1747827716538.webp)