What to Include in Your Packaging Design Brief?

A comprehensive packaging design brief is crucial when working with suppliers on customizable packaging for your skincare products. This document serves as the foundation for your project and helps ensure that both you and your supplier are aligned on expectations and goals.

Brand Identity and Vision

Start by clearly articulating your brand's identity, values, and vision. This includes your target audience, brand personality, and the emotional response you want to evoke with your packaging. Provide examples of existing packaging designs that resonate with your brand aesthetic, as well as those that don't align with your vision.

Product Specifications

Detail the specific requirements of your skincare product, including:

- Product type (e.g., cream, serum, oil)

- Viscosity and texture

- Volume or weight of the product

- Any special dispensing needs (e.g., pump, dropper, airless system)

Material Preferences and Sustainability Goals

Outline your preferences for packaging materials, considering both aesthetics and sustainability. Specify if you require recyclable, biodegradable, or PCR (post-consumer recycled) materials. Companies like Topfeelpack offer eco-friendly options that align with global sustainability standards, ensuring your packaging meets both environmental regulations and brand values.

Design Elements and Branding

Provide detailed information about your desired design elements, including:

- Color palette and finishes (e.g., matte, glossy, metallic)

- Typography and logo placement

- Unique shapes or structural designs

- Special features or embellishments (e.g., embossing, hot stamping)

Regulatory Compliance

Specify any regulatory requirements your packaging must meet, such as EU REACH, FDA, or CA Prop 65 standards. This ensures that your supplier can provide the necessary documentation and comply with relevant regulations.

Timeline and Budget

Clearly communicate your project timeline, including key milestones and the desired launch date. Be realistic about your budget constraints and discuss any flexibility in terms of materials or design elements that could impact costs.

How to Ensure Quality Control with Custom Orders?

Quality control is paramount when working with suppliers on bespoke skincare packaging. Implementing a robust quality assurance process helps maintain consistency, functionality, and brand integrity across your product line.

Establish Clear Quality Standards

Work with your supplier to define specific quality standards for your custom packaging. This should include tolerances for dimensions, color matching, material composition, and functional requirements. Document these standards in a formal quality control agreement.

Request Prototypes and Samples

Before committing to a full production run, request prototypes or samples of your custom packaging. This allows you to assess the quality, functionality, and overall aesthetic of the packaging. Topfeelpack, for example, offers quick prototyping services, delivering new product samples within 7-15 days, enabling you to make informed decisions before mass production.

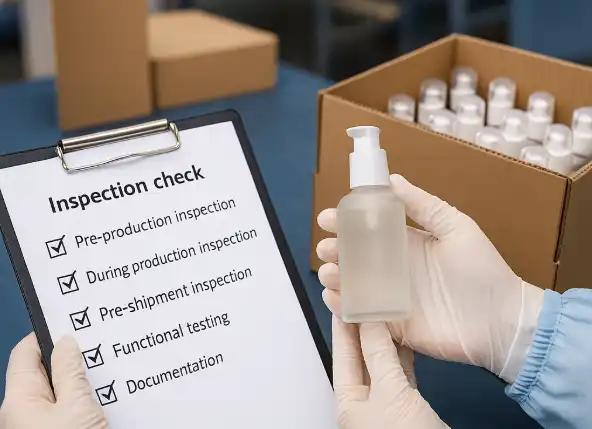

Implement a Multi-Stage Inspection Process

Develop a comprehensive inspection process that includes:

- Pre-production inspection: Review raw materials and components before manufacturing begins

- During production inspection: Regular checks throughout the manufacturing process

- Pre-shipment inspection: Final quality check before the order is shipped

Conduct Functional Testing

Perform rigorous functional testing on your custom packaging to ensure it meets all performance requirements. This may include:

- Leak tests for bottles and containers

- Compatibility tests with your product formulation

- Stability tests under various environmental conditions

- Drop tests to assess durability

Request Relevant Documentation

Ensure your supplier provides all necessary quality-related documentation, such as:

- Material certifications (e.g., COA - Certificate of Analysis)

- Safety data sheets (MSDS)

- Test reports for regulatory compliance

Establish Open Communication Channels

Maintain regular communication with your supplier throughout the production process. This allows for quick resolution of any issues that may arise and ensures that quality standards are consistently met.

Common Mistakes When Ordering Custom Skincare Jars

Avoid these frequent pitfalls when working with suppliers on bespoke skincare packaging for your skincare products:

Underestimating Lead Times

One of the most common mistakes is not allowing enough time for the custom packaging process. Creating bespoke packaging often requires multiple rounds of design revisions, prototyping, and testing. Rushing this process can lead to compromises in quality or design. Work with suppliers like Topfeelpack that offer fast customization services, capable of delivering new products within 30-45 days, to help manage your timeline effectively.

Neglecting Compatibility Testing

Failing to thoroughly test the compatibility between your skincare formulation and the packaging material can lead to product degradation or contamination. Always conduct comprehensive compatibility tests to ensure the longevity and efficacy of your product.

Overlooking Minimum Order Quantities (MOQs)

Custom packaging often comes with higher minimum order quantities compared to stock options. Failing to consider these MOQs can lead to overordering or budget overruns. Discuss flexible MOQ options with your supplier, especially if you're a smaller brand or launching a new product line.

Ignoring Sustainability Considerations

In today's environmentally conscious market, overlooking sustainability in your packaging design can be a significant oversight. Consider eco-friendly materials and designs that align with your brand values and meet consumer expectations for sustainable packaging.

Focusing Solely on Aesthetics

While visual appeal is crucial, it's a mistake to prioritize aesthetics over functionality. Ensure that your custom packaging not only looks great but also effectively protects and dispenses your product. Consider factors like air-tightness, UV protection, and ease of use.

Neglecting Scalability

When designing custom packaging, it's important to consider your future growth. Choosing overly complex or expensive packaging solutions may become unsustainable as your brand scales. Work with your supplier to develop packaging that can be efficiently produced at larger volumes without compromising on quality or design.

Failing to Secure Proper Documentation

Not obtaining all necessary documentation, such as material certifications and regulatory compliance reports, can lead to issues down the line. In order to back up quality assurance and satisfy regulatory standards, you need always have thorough documentation for your bespoke packaging.

You may design bespoke skincare packaging that strengthens your brand identification, safeguards your product, and pleases your clients by avoiding these typical pitfalls and working closely with seasoned suppliers.

Conclusion

The thrilling adventure of designing unique packaging for your skincare items may have a major influence on the success of your company. You can create bespoke skincare packaging that not only looks beautiful but also performs perfectly and is consistent with your brand's values by knowing what to include in your packaging design brief, putting in place effective quality control procedures, and avoiding common errors.

Are you prepared to take your skincare business to the next level with tailored packaging? Custom packaging that is both aesthetically pleasing and environmentally friendly is Topfeelpack's forte. You can keep your product fresh for longer and keep its efficacy intact with our state-of-the-art airless bottles. We can make your packing dreams a reality with our lightning-fast customisation, affordable prices, and lightning-fast delivery. Feel the difference firsthand when you collaborate with packaging specialists that are well-versed in the specific requirements of the skincare business. Contact us today at pack@topfeelgroup.com to start your custom packaging journey and take your brand to the next level.

References

1. Smith, J. (2023). The Art of Custom Skincare Packaging Design. Journal of Cosmetic Innovation, 15(2), 78-92.

2. Johnson, A., & Brown, L. (2022). Sustainable Packaging Solutions for the Beauty Industry. Green Cosmetics Quarterly, 8(4), 112-128.

3. Lee, S. (2023). Quality Control Strategies in Custom Cosmetic Packaging. International Journal of Packaging Technology, 19(3), 245-260.

4. Garcia, M., & Taylor, R. (2022). Consumer Perceptions of Luxury Skincare Packaging. Beauty Marketing Review, 11(1), 33-49.

5. Wong, H. (2023). Navigating Regulatory Compliance in Cosmetic Packaging Design. Regulatory Affairs in Cosmetics, 7(2), 180-195.

6. Anderson, K. (2022). The Impact of Packaging on Skincare Product Efficacy. Journal of Cosmetic Science, 73(4), 301-315.

- 副本_1745399213966.webp)

_1747827716538.webp)