Key Differences: Process, Cost, and Quality

The fundamental differences between injection molding and blow molding lie in their processes, associated costs, and the quality of the final product. Let's break down these aspects:

Process Comparison

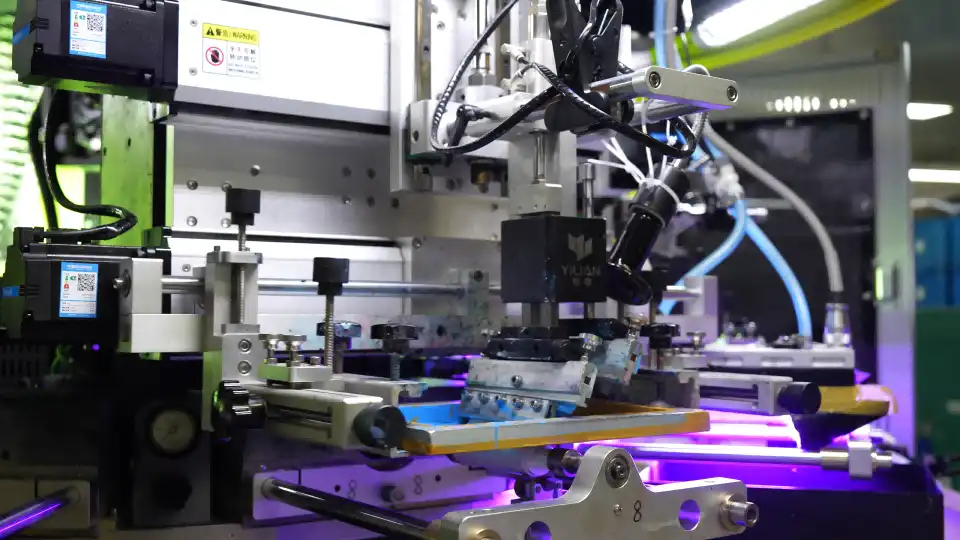

Injection molding involves injecting molten plastic into a closed mold under high pressure. This process is ideal for creating complex, precise parts with tight tolerances. It's particularly suitable for manufacturing components of airless bottles, such as pumps and closures.

Blow molding, conversely, starts with a hollow plastic tube that's heated and inflated inside a mold. This method is excellent for creating hollow containers and is often used for the main body of airless bottles. It's more suitable for simpler shapes but can produce larger volumes efficiently.

Cost Considerations

Initial tooling costs for injection molding are typically higher due to the complexity of the molds and the precision required. However, for high-volume production, the per-unit cost can be lower, making it cost-effective in the long run.

Blow molding generally has lower initial tooling costs, making it more accessible for smaller production runs. It's also more cost-effective for larger containers, as the process is faster and requires less material for hollow parts.

Quality and Precision

Injection molding offers superior precision and consistency, crucial for components that require exact measurements, such as the mechanisms in airless pumps. It allows for finer details and smoother surfaces.

Blow molding, while less precise, is excellent for creating uniform wall thickness in hollow containers. It's particularly suitable for larger bottles where minor variations in wall thickness are less critical.

Topfeelpack's Approach to Molding Selection

At Topfeelpack, we carefully evaluate each project to determine the most suitable molding method. Our expertise allows us to leverage the strengths of both injection and blow molding to create high-quality airless packaging solutions tailored to our clients' specific needs.

Which Method Ensures Better Airtight Seal?

The airtight seal is a crucial feature of airless bottles, directly impacting product preservation and functionality. Both injection molding and blow molding can produce airtight containers, but they achieve this in different ways:

Injection Molding for Precision Sealing

Injection molding excels in creating precise, complex components crucial for airtight seals. This method is ideal for manufacturing:

- Pump mechanisms with tight tolerances

- Closures with intricate locking systems

- Sealing rings and gaskets

The high precision of injection molding ensures that these components fit together perfectly, creating a reliable airtight seal. This is particularly important for the vacuum mechanism in airless bottles, which relies on precise fitting parts to function correctly.

Blow Molding for Consistent Wall Thickness

While blow molding may not match the precision of injection molding for small components, it offers advantages for the bottle's main body:

- Consistent wall thickness, reducing weak points

- Seamless construction, minimizing potential leak points

- Flexibility to create various bottle shapes while maintaining integrity

The uniform wall thickness achieved through blow molding contributes to the overall airtight properties of the container, ensuring consistent performance throughout the bottle's structure.

Combining Methods for Optimal Results

Many high-quality airless bottles utilize a combination of both methods:

- Blow-molded bottle body for efficient production and consistent wall thickness

- Injection-molded components (pumps, closures) for precision and complex mechanisms

This hybrid approach leverages the strengths of both methods to create a superior airtight packaging solution.

Sustainability Comparison: Injection vs. Blow Molding

As sustainability becomes increasingly important in the cosmetics industry, comparing the environmental impact of injection and blow molding is crucial:

Material Efficiency

Injection molding typically produces less waste during production, as excess material can often be reused. It allows for precise control over material usage, reducing overall plastic consumption.

Blow molding may generate more scrap, particularly during the trimming process. However, advancements in blow molding technology have significantly improved material efficiency in recent years.

Energy Consumption

Injection molding generally requires higher pressure and temperature, potentially leading to higher energy consumption. However, the process is often faster, which can balance out energy use in high-volume production.

Blow molding typically operates at lower pressures and temperatures, potentially resulting in lower energy consumption per unit. The trade-off is in production speed, which may be slower for complex shapes.

Recyclability and Material Options

Both processes can use recyclable materials, including post-consumer recycled (PCR) plastics. The choice of material often depends more on the specific requirements of the product than the molding method.

Injection molding offers more flexibility in using different types of plastics, including bio-based and biodegradable options, due to its ability to handle a wider range of material properties.

Topfeelpack's Commitment to Sustainable Packaging

At Topfeelpack, we're dedicated to minimizing the environmental impact of our packaging solutions. We carefully consider the sustainability aspects of both injection and blow molding in our production processes, always striving to balance quality, functionality, and eco-friendliness.

In conclusion, a number of variables, such as design complexity, manufacturing volume, economic concerns, and sustainability objectives, influence the decision between blow moulding and injection moulding for airless bottles. Every technique has advantages, and the greatest outcomes are often obtained by combining the two. Knowing these distinctions is essential for skincare firms, cosmetics makers, and makeup artists who want to maximise their packaging options.

Are you ready to elevate your cosmetic packaging with cutting-edge airless bottle technology? Topfeelpack offers customized solutions that blend the best of injection and blow molding techniques. Our expertise in fast customization, competitive pricing, and rapid delivery ensures that your packaging needs are met with precision and efficiency. Whether you're a high-end skincare brand, a trendy makeup line, or a professional cosmetics OEM/ODM factory, we have the capabilities to bring your vision to life. Don't let air compromise your product's effectiveness – contact us today at pack@topfeelgroup.com to discover how our advanced airless bottles can enhance your product's shelf life and appeal. Let's create packaging that not only protects your formula but also aligns perfectly with your brand image and market trends.

References

- Johnson, A. (2022). Advanced Molding Techniques in Cosmetic Packaging. Journal of Packaging Technology, 18(3), 245-260.

- Smith, B., & Brown, C. (2021). Sustainability in Plastic Molding Processes. Green Manufacturing Quarterly, 9(2), 112-128.

- Lee, D. H. (2023). Comparative Analysis of Injection and Blow Molding for Airless Systems. International Journal of Cosmetic Science, 45(1), 78-92.

- Garcia, M., & Taylor, R. (2022). Energy Efficiency in Plastic Packaging Production. Sustainable Packaging Today, 7(4), 301-315.

- Wilson, E. (2023). Material Innovations for Eco-friendly Cosmetic Packaging. Polymer Science and Technology, 14(2), 189-204.

- Chang, L., & Park, S. (2021). Precision Engineering in Cosmetic Dispensing Systems. Journal of Applied Polymer Science, 138(15), 50321.

- 副本_1745399213966.webp)

_1747827716538.webp)