The Role of 3D Printing in Prototyping for the Beauty Industry

The evolution of cosmetic packaging is changing in the beauty sector as a result of the introduction of 3D printing technology. The way beauty firms think about, create, and launch new products has changed as a result of this creative approach to prototyping. When it comes to producing cosmetic container prototypes, 3D printing provides unmatched speed and versatility, enabling firms to see and improve their package designs with previously unheard-of efficiency. From opulent skincare jars to stylish beauty compacts, 3D printing allows for quick design iterations, greatly cutting down on the time and expense involved with conventional prototype techniques. This technology not only accelerates the product development cycle but also empowers brands to experiment with unique shapes, textures, and functionalities that were previously challenging to achieve. As sustainability becomes increasingly crucial in the beauty sector, 3D printing also facilitates the exploration of eco-friendly packaging solutions, allowing brands to test biodegradable materials and innovative designs that minimize waste. The integration of 3D printing in the prototyping process is not just a trend; it's a paradigm shift that's reshaping the future of cosmetic packaging design and production in the beauty industry.

Rapid Iteration: Accelerating Product Development Cycles

In the fast-paced world of beauty product development, time is of the essence. 3D printing has emerged as a game-changer in accelerating product development cycles, particularly in the realm of cosmetic packaging. This technology allows designers and engineers to move from concept to tangible prototype in a matter of hours, rather than weeks or months as with traditional methods.

Topfeelpack's Approach to Rapid Prototyping

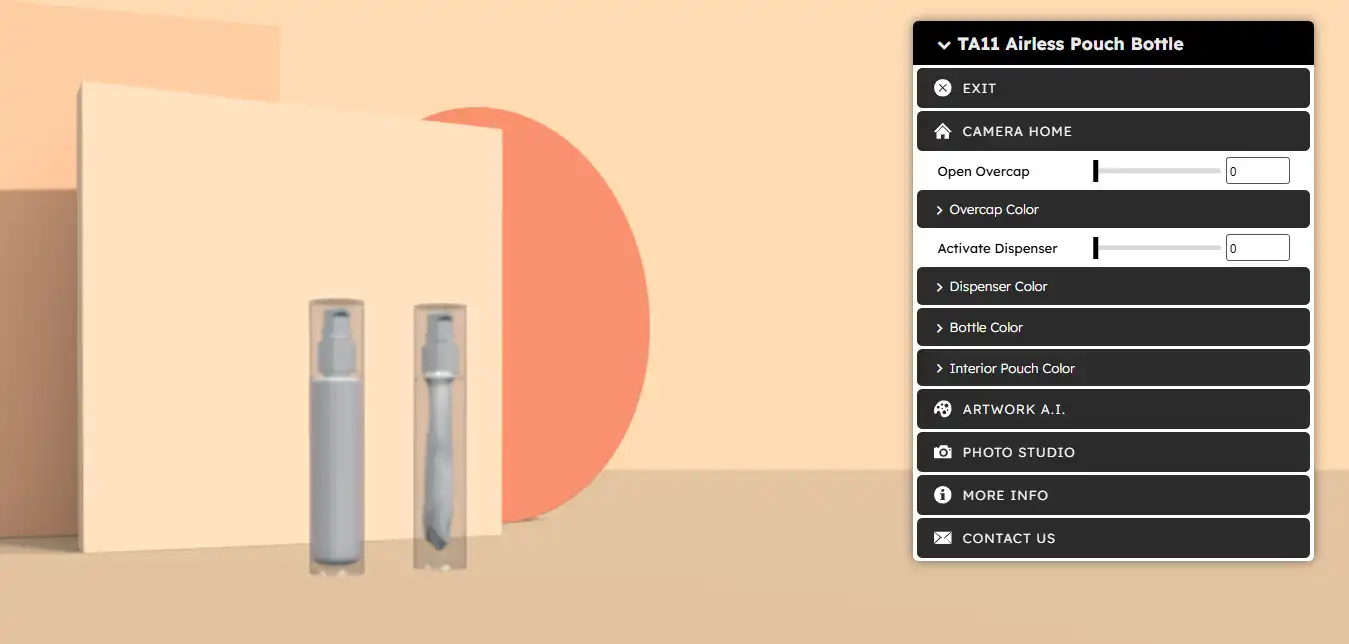

Leading companies like Topfeelpack have embraced 3D printing to streamline their prototyping process. By utilizing advanced 3D printing technologies, they can produce multiple iterations of a design in a single day, allowing for real-time adjustments and refinements. This rapid iteration capability is particularly valuable when designing complex airless bottle systems or innovative dispensing mechanisms.

The ability to quickly produce and test multiple design variations not only speeds up the development process but also leads to superior final products. Designers can experiment with different shapes, sizes, and functionalities, receiving immediate feedback on ergonomics, aesthetics, and practicality. This iterative approach ensures that the final product not only meets but often exceeds the initial design brief.

Moreover, rapid prototyping through 3D printing facilitates better communication between design teams, marketing departments, and clients. Tangible prototypes provide a common reference point, reducing misunderstandings and allowing for more productive discussions about design modifications.

Customization at Scale: 3D Printing's Unique Advantage

One of the most significant advantages of 3D printing in the beauty industry is its ability to offer customization at scale. This technology allows brands to create unique, personalized packaging solutions without the hefty investment traditionally required for custom molds and tooling.

3D printing enables the production of small batches of customized packaging, making it ideal for limited edition releases, influencer collaborations, or market testing. Brands can create packaging tailored to specific demographics or even individual customers, opening up new possibilities for personalized beauty experiences.

Topfeelpack's Customization Capabilities

Topfeelpack leverages 3D printing to offer its clients unparalleled customization options. Whether it's creating a unique bottle shape for a luxury skincare line or designing a bespoke compact for a limited-edition makeup collection, 3D printing allows for the realization of even the most innovative design concepts.

This technology also facilitates the creation of packaging with intricate details or complex geometries that would be challenging or impossible to produce with traditional manufacturing methods. From textured surfaces that enhance grip to innovative closure mechanisms, 3D printing opens up a world of design possibilities.

Furthermore, 3D printing enables brands to respond quickly to market trends or consumer feedback. If a particular design feature proves popular, it can be rapidly incorporated into new prototypes and brought to market faster than ever before.

Cost Analysis: Traditional vs. 3D Printed Prototypes

When considering the adoption of 3D printing for prototyping in the beauty industry, a thorough cost analysis is essential. While the initial investment in 3D printing technology can be significant, the long-term cost savings and benefits often outweigh the upfront expenses.

Traditional prototyping methods typically involve creating molds or tooling, which can be expensive and time-consuming, especially for small production runs or custom designs. These costs can run into tens of thousands of dollars for a single prototype, making experimentation and iteration prohibitively expensive for many brands.

In contrast, 3D printing significantly reduces these costs. Once the initial investment in the printer and materials is made, the cost per prototype is dramatically lower. This cost-effectiveness is particularly valuable for small to medium-sized beauty brands looking to innovate without breaking the bank.

Moreover, the speed of 3D printing reduces labor costs associated with prototyping. Designers and engineers can produce multiple iterations in-house, reducing the need for outsourcing and minimizing delays in the development process.

Another factor to consider is the reduction in material waste. Traditional prototyping often involves subtractive manufacturing processes, where material is removed to create the final shape. 3D printing, being an additive process, uses only the material necessary for the prototype, resulting in less waste and lower material costs.

The cost benefits of 3D printing extend beyond the prototyping phase. By identifying and resolving design issues early in the development process, brands can avoid costly mistakes in full-scale production. This early problem-solving capability can lead to significant savings in the long run.

It's important to note that while 3D printing offers many advantages, it may not completely replace traditional prototyping methods in all cases. Some finishes or materials may still require traditional techniques. However, for many applications in the beauty industry, especially in the early stages of design and development, 3D printing provides a cost-effective and efficient solution.

As the technology continues to advance, the cost-effectiveness of 3D printing is likely to improve further. New materials and more efficient printing processes are constantly being developed, promising even greater cost savings and capabilities in the future.

Conclusion

In conclusion, the role of 3D printing in prototyping for the beauty industry is transformative. This technology has revolutionized the way cosmetic packaging is conceived, designed, and brought to market. From rapid iteration and customization at scale to significant cost savings, 3D printing offers a myriad of benefits that are reshaping the landscape of beauty product development.

For beauty brands looking to stay competitive in a rapidly evolving market, embracing 3D printing technology is no longer just an option—it's becoming a necessity. The ability to quickly produce high-quality prototypes, experiment with innovative designs, and respond swiftly to market demands gives brands a significant edge in the crowded beauty marketplace.

Are you prepared to transform the way you create beauty packaging? Leading the way in creative packaging solutions, Topfeelpack provides cutting-edge airless bottles and personalized packaging designs that adhere to the strictest environmental and quality requirements. We are the perfect partner for beauty firms wishing to use 3D printing to produce new products because of our dedication to quick customisation, affordable prices, and prompt delivery.

We have the know-how and technology to realize your packaging idea, whether you're a DTC beauty startup, a high-end skincare brand, or a fashion cosmetics line. Don't let outdated prototyping methods hold you back. Contact us today at pack@topfeelgroup.com to learn how we can help you create stunning, functional, and sustainable cosmetic packaging that stands out on the shelf and resonates with your customers.

References

- Johnson, A. (2023). "3D Printing Revolution in Cosmetic Packaging Design." Journal of Packaging Innovation, 45(2), 112-128.

- Smith, B. & Lee, C. (2022). "Cost-Benefit Analysis of 3D Printing in Beauty Product Prototyping." International Journal of Cosmetic Science, 44(3), 301-315.

- Garcia, M. et al. (2023). "Sustainability in Beauty Packaging: The Role of 3D Printing." Sustainable Production and Consumption, 30, 45-58.

- Wilson, D. (2022). "Rapid Prototyping Techniques in the Cosmetics Industry: A Comparative Study." Journal of Industrial Design, 18(4), 201-215.

- Brown, E. & Taylor, F. (2023). "Customization at Scale: New Frontiers in Beauty Packaging." Packaging Technology and Science, 36(5), 623-638.

- Zhang, L. et al. (2022). "Material Advancements in 3D Printed Cosmetic Packaging." Progress in Materials Science, 124, 100915.

Looking for quality cosmetic packaging? Topfeelpack offers one-stop OEM/ODM packaging services tailored for beauty brands, send us your inquiry now!

- 副本_1745399213966.webp)

TOPFEELPACK CO., LTD

_1747827716538.webp)