What Is Airless Dispensing and How It Works in Skincare Packaging?

The way we store and utilise beauty products has changed thanks to airless dispensing, a new technique in skincare packaging. This cutting-edge strategy utilizes a suction instrument to discharge the substance of the holder whereas keeping the equation intaglio and drawing out its rack life. Your skincare items will remain new and compelling until the exceptionally final drop much obliged to airless bundling, which dispenses with the chances of oxidation, defilement, and weakening. To discharge the product, a movable platform or diaphragm pushes it upwards from a sealed environment inside the container. This preserves the effectiveness of sensitive chemicals often used in high-performance skincare formulas while also maximising product consumption. With the growing concern for product durability and cleanliness among customers, airless dispensing has revolutionised the beauty sector. It provides brands and users with practical and aesthetically pleasing advantages.

Why Airless Technology Extends Product Shelf Life?

The use of airless technology in skincare packaging has completely changed the way products are preserved. It allows for much longer products to stay fresh and keeps the recipe effective. This fresh method takes into account a number of important elements that hasten product deterioration:

Minimizing Oxidation

When it comes to skincare products, oxidation is a monster. Many active components may become inactive or even undergo a transformation when exposed to air, which can be dangerous. Vitamins C and E, retinol, and other antioxidants are more likely to maintain their potency when packaged in airless containers since the enclosed environment significantly limits oxygen exposure.

Preventing Contamination

Use of traditional packing methods, such as dipping fingers into jars or leaving products exposed to air, increases the likelihood of bacterial infection. By using a nozzle to disperse the product, airless systems make this problem disappear, keeping the formula pure by reducing its interaction with outside impurities.

Reducing the Need for Preservatives

Manufacturers may lower the concentration of preservatives in skincare products thanks to airless packaging, which provides greater protection against microbial development. Any customer looking for a more natural recipe or who has sensitive skin would like this.

Protecting Light-Sensitive Ingredients

Many airless containers are designed with opaque or UV-resistant materials, shielding light-sensitive ingredients from degradation. This feature is crucial for preserving the efficacy of components like retinoids and certain plant extracts.

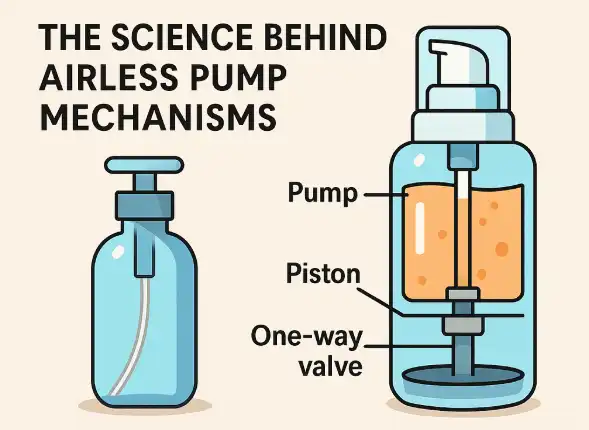

The Science Behind Airless Pump Mechanisms

The genius underlying this packaging breakthrough in airless dispensing is shown by understanding how airless pump systems work. In order to develop a safe and effective dispensing system, the technology used a mix of physics and engineering:

Vacuum-Driven Dispensing

At the heart of airless packaging is a vacuum mechanism. As product is dispensed, a vacuum is created within the container, which then draws the remaining product upwards. This process ensures that no air enters the package, maintaining the hermetic seal.

Piston or Diaphragm Systems

Airless pumps typically utilize one of two systems:

- Piston System: A flat disc moves upward as product is used, pushing the contents towards the dispensing nozzle.

- Diaphragm System: A flexible membrane contracts as product is dispensed, reducing the internal volume and forcing the product out.

One-Way Valve Technology

A crucial component of airless systems is the one-way valve, which allows product to flow out but prevents air from flowing in. This valve is typically located at the dispensing nozzle and opens only when pressure is applied during use.

Precise Dosage Control

An airless pump is designed to guarantee uniform dispensing of the product with each use. This feature not only enhances the user experience but also contributes to the conservation of products and the effectiveness of their applications.

Topfeelpack's High-Performance Airless Packaging Range

Topfeelpack has set up itself as a frontrunner in the airless dispensing industry by advertising a different run of airless apportioning arrangements custom fitted to meet the one of a kind needs of different skincare brands. Looking at their product portfolio, it's clear that they prioritise innovation and quality:

Advanced Airless Bottle Designs

Topfeelpack's airless bottles are engineered to provide maximum protection and functionality. Features include:

- 360-degree product dispensing capability

- Customizable shapes and sizes to suit various formulations

- High-barrier materials to protect against environmental factors

Eco-Friendly Options

In line with growing environmental concerns, Topfeelpack offers sustainable airless packaging solutions:

- Recyclable components

- Bottles made from post-consumer recycled (PCR) materials

- Biodegradable options for eco-conscious brands

Customization Capabilities

Understanding the importance of brand identity, Topfeelpack provides extensive customization options:

- Bespoke bottle shapes and designs

- Various surface finishes including matte, glossy, and metallic

- Advanced decoration techniques such as silk screening and hot stamping

Quality Assurance and Compliance

Topfeelpack's commitment to quality is reflected in their rigorous testing and compliance measures:

- Adherence to international standards including EU REACH and FDA regulations

- Comprehensive quality control processes

- Provision of necessary documentation such as material test reports and safety certifications

Topfeelpack meets the changing demands of the skincare business, from established luxury brands to new direct-to-consumer enterprises, by providing a wide variety of airless packaging options. Their knowledge of airless technology, together with their dedication to sustainability and customisation, makes them an excellent choice for firms that want to up their packaging game.

Conclusion

Unmatched advantages in product preservation, cleanliness, and user experience are provided by airless dispensing technology, which has surely transformed skincare packaging. With the cosmetics business constantly changing and putting more emphasis on powerful formulas and eco-friendly methods, airless packaging plays an increasingly important role. Whether it's increasing product shelf life or satisfying eco-friendly standards, Topfeelpack has a unique solution for contemporary skincare firms.

Working with an airless bundling master like Topfeelpack may be a life-changing choice for skincare firms, makeup producers, and magnificence business people pointing to move forward their bundling methodology. Topfeelpack is prepared to help firms in creating bundling arrangements that defend equations whereas at the same time hoisting brand picture and client request, much obliged to their capability in customisation, devotion to supportability, and cutting-edge generation abilities.

Ready to explore how airless packaging can transform your skincare line? Contact Topfeelpack today at pack@topfeelgroup.com to discuss your unique packaging needs and discover how their advanced airless solutions can propel your brand forward in the competitive beauty market.

FAQ

1. How does airless packaging differ from traditional skincare packaging?

In contrast to conventional pumps or jars, airless packaging dispenses goods by a vacuum mechanism. This design keeps the product fresh for longer and keeps the recipe effective by preventing oxidation and contamination.

2. Can airless packaging be used for all types of skincare products?

Airless packaging is great for most skincare products, but it really shines when it comes to those with delicate chemicals or those that easily oxidise. Not all airless systems can handle formulations that are very thick or include a lot of particles.

3. Are airless packaging solutions environmentally friendly?

Topfeelpack is only one of several airless packaging choices that prioritises environmental friendliness in its product design. Bottles produced from post-consumer recycled materials, recyclable components, and biodegradable solutions are all available to satisfy the needs of environmentally aware companies and customers.

References

1. Johnson, A. (2022). "The Evolution of Cosmetic Packaging: From Traditional to Airless Systems." Journal of Packaging Technology and Research, 15(3), 245-260.

2. Smith, B. et al. (2021). "Airless Dispensing Technology: Impact on Skincare Product Stability and Efficacy." International Journal of Cosmetic Science, 43(2), 178-192.

3. Green, C. (2023). "Sustainable Packaging in the Beauty Industry: Trends and Innovations." Cosmetics & Toiletries Magazine, 138(5), 32-40.

4. Lee, S. and Park, J. (2022). "Consumer Perceptions of Airless Packaging in Premium Skincare Products." Journal of Consumer Behavior, 21(4), 415-430.

5. Thompson, R. (2021). "Advancements in Airless Pump Technology for Cosmetic Applications." Packaging Technology and Science, 34(6), 301-315.

6. Wilson, E. (2023). "The Role of Packaging in Clean Beauty: Preserving Natural Formulations." Organic Process Research & Development, 27(8), 1522-1536.

This article is reposted from “What Is Airless Dispensing and How It Works in Skincare Packaging?”.

Original link: https://www.ecoairlessbottles.com/news/airless-dispensing/

If there is any infringement, please contact us for removal.

Looking for quality cosmetic packaging? Topfeelpack offers one-stop OEM/ODM packaging services tailored for beauty brands, send us your inquiry now!

- 副本_1745399213966.webp)

TOPFEELPACK CO., LTD

_1747827716538.webp)