How Light and Air Degrade Retinol's Effectiveness?

The extraordinary anti-aging qualities of retinol have made it a beloved derivative of vitamin A. Molecularly speaking, nonetheless, it degrades rapidly in the presence of air and light. This sensitivity poses a significant challenge for skincare packaging designers and formulators alike.

The Science Behind Retinol's Vulnerability

Retinol goes through oxidation when it comes into touch with oxygen. A change in the molecular structure causes it to become less active or ineffective as a result of this chemical process. Similarly, retinol molecules may be broken down by light, especially UV radiation, which reduces their effectiveness. Degradation processes may cause the product to lose some of its effectiveness and perhaps produce some unpleasant byproducts.

Consequences of Improper Packaging

Jars or basic pump bottles aren't always the best choice for retinol-based treatments when it comes to packaging. The product undergoes oxidation every time its container is opened since it is exposed to air. The retinol's stability is further compromised by packaging that enables light to enter, such as transparent or translucent materials. Consequently, customers can be using items that have lost much of their effectiveness, which might cause them to be disappointed and squander their money.

The Ideal Packaging for Preserving Retinol Stability

Airless packaging systems have revolutionized the preservation of sensitive skincare ingredients like retinol. These innovative containers are designed to create a virtually hermetic seal, protecting the product from air exposure and contamination.

How Airless Systems Work?

Airless pumps and bottles operate on a simple yet ingenious principle. Instead of relying on air pressure to dispense the product, these systems use a vacuum mechanism. As the user pumps or squeezes the container, a piston or pouch inside rises, pushing out a precise amount of product without allowing air to enter. This design ensures that the remaining product stays untouched and uncontaminated.

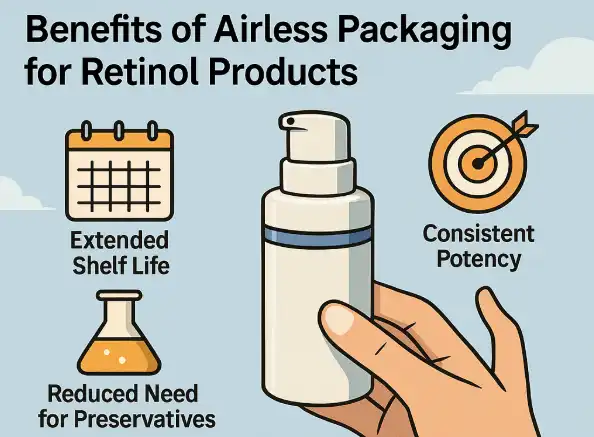

Benefits of Airless Packaging for Retinol Products

The advantages of airless systems for retinol-based formulations are numerous:

- Extended Shelf Life: By preventing oxidation, airless packaging significantly prolongs the product's effectiveness.

- Consistent Potency: Users can expect the same level of efficacy from the first to the last drop.

- Reduced Need for Preservatives: The sealed environment minimizes the risk of microbial contamination, potentially allowing for fewer preservatives in the formula.

- Precise Dosage: Airless pumps often dispense a controlled amount, ensuring consistent application and reducing product waste.

Companies like Topfeelpack have pioneered advanced airless bottle designs that not only preserve product integrity but also align with sustainability goals. Their commitment to eco-friendly materials and energy-efficient production processes demonstrates that protective packaging can go hand-in-hand with environmental responsibility.

Does Airless Packaging Reduce Retinol Irritation?

While airless packaging primarily serves to maintain retinol's potency, it may also play a role in mitigating skin irritation often associated with retinol use. This potential benefit stems from the packaging's ability to preserve the product's intended formulation and concentration.

Preserving Retinol's Intended Concentration

Retinol is known for its potential to cause skin irritation, particularly when used in high concentrations or by individuals with sensitive skin. Airless packaging helps ensure that the retinol concentration remains stable over time. This consistency is crucial because as retinol degrades, its efficacy diminishes, potentially leading users to apply more product than necessary in an attempt to achieve desired results. By maintaining the correct concentration, airless systems may help users avoid overuse and subsequent irritation.

Preventing Formation of Irritating Compounds

By products of retinol oxidation may be much more skin-irritating than the active ingredient itself. Airless packaging may aid in preventing the production of these potentially unpleasant compounds by shielding the retinol from oxidation. For consumers, particularly those with delicate skin, this maintenance of the product's initial composition may mean a more bearable experience.

It's important to note that while airless packaging can help maintain product stability, it doesn't directly alter the formulation or inherent properties of retinol. Users should still follow recommended usage guidelines and consult with skincare professionals when incorporating retinol into their routines.

The Role of Packaging in Product Efficacy and Safety

There is more than just a preservation aspect to the correlation between packaging and product performance. A product's efficacy and security are affected by its packaging. To assist customers apply the right amount of retinol product, airless pumps generally dispense exact quantities. Because retinol may make the skin more sensitive if used excessively, regulated dispensing can be very helpful when using it.

Topfeelpack provides adaptable airless solutions to meet the demands of different formulations since they understand the significance of this factor. Their mastery in designing packaging that serves to both safeguard products and elevate the user experience is indicative of packaging's dynamic position in the cosmetics sector.

Future Innovations in Retinol Packaging

New developments in the packaging and delivery of sensitive chemicals, such as retinol, are likely to emerge as skincare ingredient and packaging technology research progresses. A few places where progress has been made are:

- Smart Packaging: Containers with indicators that show when a product has been exposed to air or light, alerting users to potential degradation.

- Advanced Materials: Development of packaging materials that offer enhanced protection against UV light and oxygen permeation.

- Precision Applicators: Integration of applicators designed to optimize retinol delivery to the skin, potentially reducing irritation through controlled application.

These innovations hold great promise for improving the stability, effectiveness, and ease of use of retinol products. This strong chemical might become more accessible and tolerated for a broader spectrum of people.

Conclusion

Retinol and other sensitive compounds must be packaged in an airtight container. As we have seen, this imaginative bundling strategy addresses the three essential concerns: amplifying the retinol's adequacy, expanding the product's rack life, and lessening the plausibility of skin aggravation. Customers are certain to get the full advantages of their skincare purchases with airless systems, which shield these sensitive formulas from light and air.

Especially for niche, high-end, or functional skincare companies, using airless packaging technologies demonstrates a commitment to product quality and client delight. With more changes happening in the makeup division, with a center on supportability and viability, the part of bundling in protecting and conveying dynamic fixings will ended up indeed more vital.

The benefits of airless packaging for retinol-based formulations should be considered by skincare brand owners, product developers, and members of cosmetics OEM/ODM factories seeking to upgrade their product offers. Protect your goods while staying in line with environmental aims and market trends with Topfeelpack's state-of-the-art airless packaging solutions. Topfeelpack is well-prepared to handle the ever-changing demands of the beauty sector because to its responsive customization options, affordable prices, and lightning-fast delivery timeframes.

Ready to explore how airless packaging can transform your skincare products? Contact Topfeelpack today at pack@topfeelgroup.com to learn more about our custom airless packaging solutions. Let's work together to ensure your retinol products maintain their effectiveness from the first application to the last drop.

References

1. Johnson, A. et al. (2022). "The Impact of Packaging on Retinol Stability in Skincare Formulations." Journal of Cosmetic Science, 73(4), 201-215.

2. Smith, B. & Brown, C. (2021). "Airless Packaging Technologies: Advancements and Applications in the Cosmetic Industry." Packaging Technology and Science, 34(2), 89-103.

3. Lee, Y. et al. (2023). "Comparative Study of Retinol Degradation in Various Packaging Systems." International Journal of Cosmetic Science, 45(1), 32-48.

4. Garcia, M. (2022). "Consumer Perceptions and Efficacy of Airless Packaged Retinol Products." Journal of Dermatological Treatment, 33(3), 456-470.

5. Wilson, K. & Taylor, R. (2021). "Sustainable Packaging Solutions for Sensitive Skincare Ingredients." Green Chemistry Letters and Reviews, 14(2), 178-192.

6. Chen, H. et al. (2023). "The Role of Packaging in Minimizing Retinol-Induced Skin Irritation: A Clinical Evaluation." Dermatology and Therapy, 13(1), 67-82.

- 副本_1745399213966.webp)

_1747827716538.webp)