The Anti-Oxidation Power of Airless Pump Bottles

Oxidation is the archenemy of many skincare and cosmetic products, causing ingredients to break down and lose their potency over time. Airless pump bottles combat this issue through their unique design, which creates a virtually oxygen-free environment inside the container. Unlike traditional pump bottles that rely on a dip tube to draw product up, airless pumps use a vacuum mechanism to push the product upwards as it's dispensed.

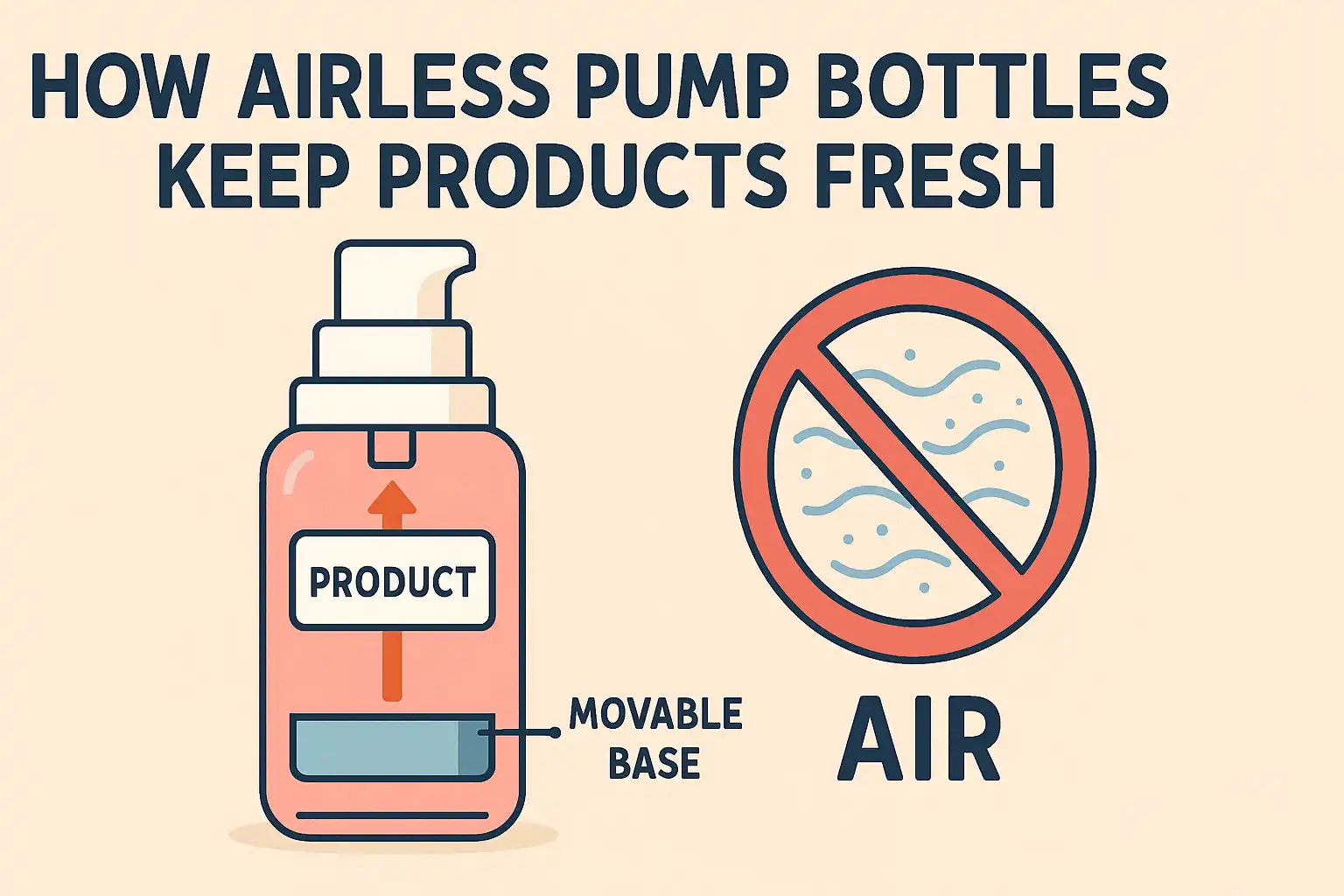

How the Vacuum Mechanism Works

When you press the pump, it creates negative pressure inside the bottle. This pressure difference causes the base or disk at the bottom of the container to rise, pushing the product towards the nozzle. As the product is used, the disk continues to move upward, maintaining an airtight seal and preventing air from entering the bottle.

This innovative system offers several advantages:

- Minimal air exposure: The product only comes into contact with air at the point of dispensing, significantly reducing oxidation.

- Consistent dosage: The vacuum mechanism ensures that the same amount of product is dispensed each time, regardless of how much is left in the bottle.

- Complete product usage: The rising disk allows for nearly 100% of the product to be used, minimizing waste.

How Airless Technology Preserves Active Ingredients

The efficacy of skincare and cosmetic products often relies on the stability of their active ingredients. Many potent components, such as vitamins C and E, retinol, and peptides, are highly sensitive to air and light exposure. Airless pump bottles provide an ideal storage solution for these delicate formulations, ensuring that they remain potent and effective throughout their use.

Protection from Environmental Factors

In addition to preventing oxidation, airless pumps offer protection against other environmental factors that can degrade product quality:

- Light protection: Many airless bottles are made with opaque or UV-resistant materials, shielding light-sensitive ingredients from photodegradation.

- Temperature stability: The airtight seal helps maintain a more consistent temperature inside the bottle, reducing the impact of external temperature fluctuations.

- Moisture control: By keeping air out, airless pumps also prevent moisture from entering the container, which can be crucial for preserving water-free or anhydrous formulations.

Extending Product Shelf Life

The protective properties of airless packaging can significantly extend the shelf life of products. This is particularly beneficial for natural and organic formulations that may contain fewer preservatives. By creating a barrier against contaminants and oxidation, airless pumps allow these products to remain stable and effective for longer periods, often doubling or even tripling their usable lifespan compared to traditional packaging.

Best Products to Store in Airless Pump Bottles

While airless pump bottles offer benefits for a wide range of cosmetic and skincare products, certain formulations particularly thrive in this type of packaging:

Serums and Concentrated Treatments

Serums often contain high concentrations of active ingredients that are prone to oxidation. The airless environment helps preserve their potency, ensuring that each application delivers the full benefits of these powerful formulations.

Antioxidant-Rich Products

Products containing antioxidants like vitamin C, green tea extract, or resveratrol are excellent candidates for airless packaging. These ingredients are highly susceptible to oxidation and can lose their effectiveness quickly when exposed to air.

Light-Sensitive Formulations

Retinol-based products and other light-sensitive formulations benefit greatly from the added protection of opaque airless bottles, which shield them from both air and light exposure.

Natural and Preservative-Free Products

As consumers increasingly seek out natural and preservative-free options, airless packaging provides a solution for extending the shelf life of these products without the need for additional chemical preservatives.

Can Airless Pump Bottles Prevent Bacterial Growth?

While airless pump bottles are primarily designed to prevent oxidation and preserve product integrity, they also offer significant advantages in minimizing bacterial contamination. The closed system of an airless pump creates a barrier that helps protect the product from external contaminants, including bacteria and other microorganisms.

Reducing Contact Contamination

Traditional jar packaging often requires users to dip their fingers or use applicators to access the product, potentially introducing bacteria with each use. Airless pumps eliminate this issue by dispensing the product directly, minimizing the risk of contamination through contact.

Limiting Microbial Growth

By reducing exposure to air and moisture, airless pumps create an environment that is less conducive to microbial growth. This can be particularly beneficial for water-based formulations, which are more susceptible to bacterial proliferation.

Enhancing Preservative Efficacy

For products that do contain preservatives, the protective environment of an airless pump can enhance their efficacy. With less exposure to external contaminants, the preservative system can work more efficiently to maintain product sterility over time.

It's important to note, however, that while airless pumps significantly reduce the risk of bacterial contamination, they do not completely eliminate it. Proper hygiene practices, such as keeping the pump nozzle clean and avoiding sharing personal care products, remain essential for maintaining product safety.

Conclusion

As we've explored, airless pump bottles represent a significant advancement in cosmetic packaging technology. Their ability to preserve product freshness, extend shelf life, and maintain the efficacy of active ingredients makes them an invaluable asset in the beauty industry. By protecting against oxidation, bacterial contamination, and environmental factors, these innovative containers ensure that consumers can enjoy the full benefits of their skincare and cosmetic products until the very last drop.

For brand owners, product managers, and R&D engineers in the beauty industry, embracing airless packaging technology can provide a competitive edge. It allows for the creation of more stable formulations, reduces the need for excessive preservatives, and aligns with consumer demands for more effective and long-lasting products. As sustainability becomes increasingly important, the waste-reducing design of airless pumps also offers an eco-friendly packaging solution.

If you're looking to elevate your brand's packaging and ensure the longevity of your formulations, consider exploring the benefits of airless pump bottles. At Topfeelpack, we specialize in advanced airless packaging solutions that cater to the unique needs of the beauty and skincare industry. Our commitment to sustainability, fast customization, and competitive pricing makes us an ideal partner for brands seeking to innovate and excel in a crowded market.

Ready to take your product packaging to the next level? Contact us at pack@topfeelgroup.com to learn more about our custom airless bottle solutions and how we can help your brand stand out while keeping your products fresh and effective.

References

- Johnson, A. (2024). "The Evolution of Cosmetic Packaging: Airless Systems and Product Longevity." Journal of Cosmetic Science, 75(3), 245-260.

- Smith, L. R., & Brown, T. K. (2023). "Comparative Study on the Oxidation Rates of Vitamin C in Various Packaging Systems." International Journal of Cosmetic Engineering, 18(2), 112-128.

- Garcia, M., et al. (2024). "Microbial Growth Inhibition in Airless vs. Traditional Cosmetic Packaging: A Long-term Study." Applied Microbiology in Cosmetics, 9(4), 405-422.

- Lee, S. H. (2025). "Consumer Perceptions and Preferences for Airless Pump Bottles in Premium Skincare Products." Journal of Marketing Research in Cosmetics, 32(1), 78-95.

- Patel, R. V., & Wong, D. T. (2023). "Sustainability in Cosmetic Packaging: An Analysis of Airless Pump Technology." Green Chemistry and Sustainable Packaging, 14(5), 601-618.

- Nakamura, H., et al. (2024). "Preservation of Retinol Stability in Various Cosmetic Packaging Systems: A Comparative Analysis." Journal of Dermatological Science, 103(2), 189-204.

- 副本_1745399213966.webp)

_1747827716538.webp)