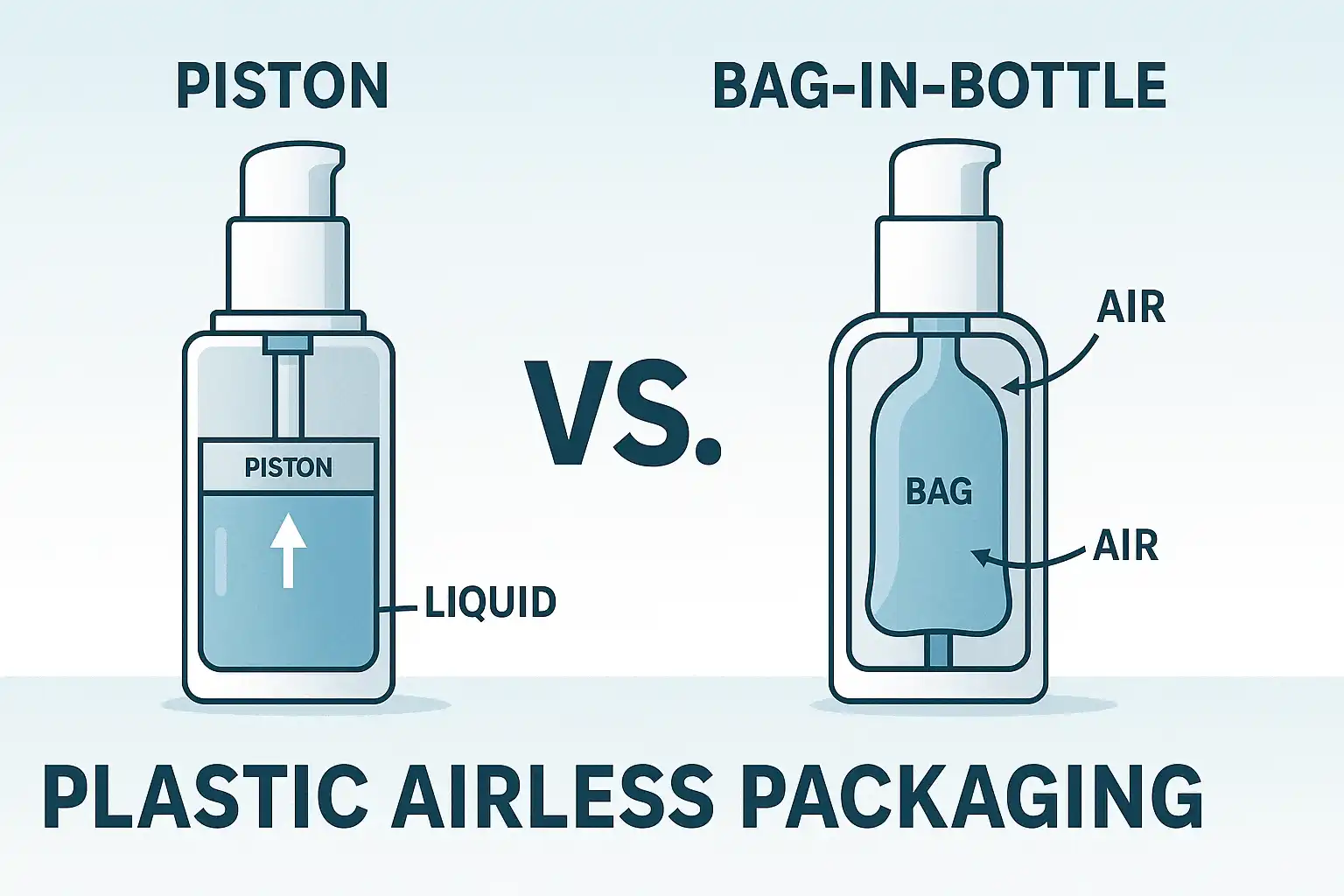

The structural differences between piston and bag-in-bottle designs

Piston-based and bag-in-bottle systems represent two distinct approaches to airless packaging technology. Each design has its unique structural components that influence product dispensing, preservation, and overall performance.

Piston-based airless packaging

Piston-based systems utilize a movable platform within the container that rises as the product is dispensed. This design typically consists of:

- A cylindrical container

- A tight-fitting piston at the base

- A non-return valve

- A dispensing mechanism (pump or nozzle)

As the user activates the pump, the product above the piston is forced out through the valve. Simultaneously, the piston moves upward, maintaining constant pressure on the remaining product and preventing air from entering the container.

Bag-in-bottle airless packaging

Bag-in-bottle systems, also known as pouch or collapsible bag systems, feature a different structural approach:

- An outer rigid container

- An inner flexible pouch or bag

- A dispensing mechanism

- A venting system

In this design, the product is contained within the flexible inner pouch. As the user dispenses the product, the pouch collapses, eliminating the need for air replacement. The space between the pouch and the outer container allows for the bag's controlled collapse.

Which airless packaging type prevents contamination better?

Both piston and bag-in-bottle systems offer superior protection against contamination compared to traditional packaging, but they achieve this goal through different mechanisms.

Contamination prevention in piston-based systems

Piston-based airless packaging excels in preventing contamination due to its hermetic seal and continuous pressure application. The advantages include:

- Minimal air contact: The rising piston maintains constant pressure, reducing the risk of air entering the container.

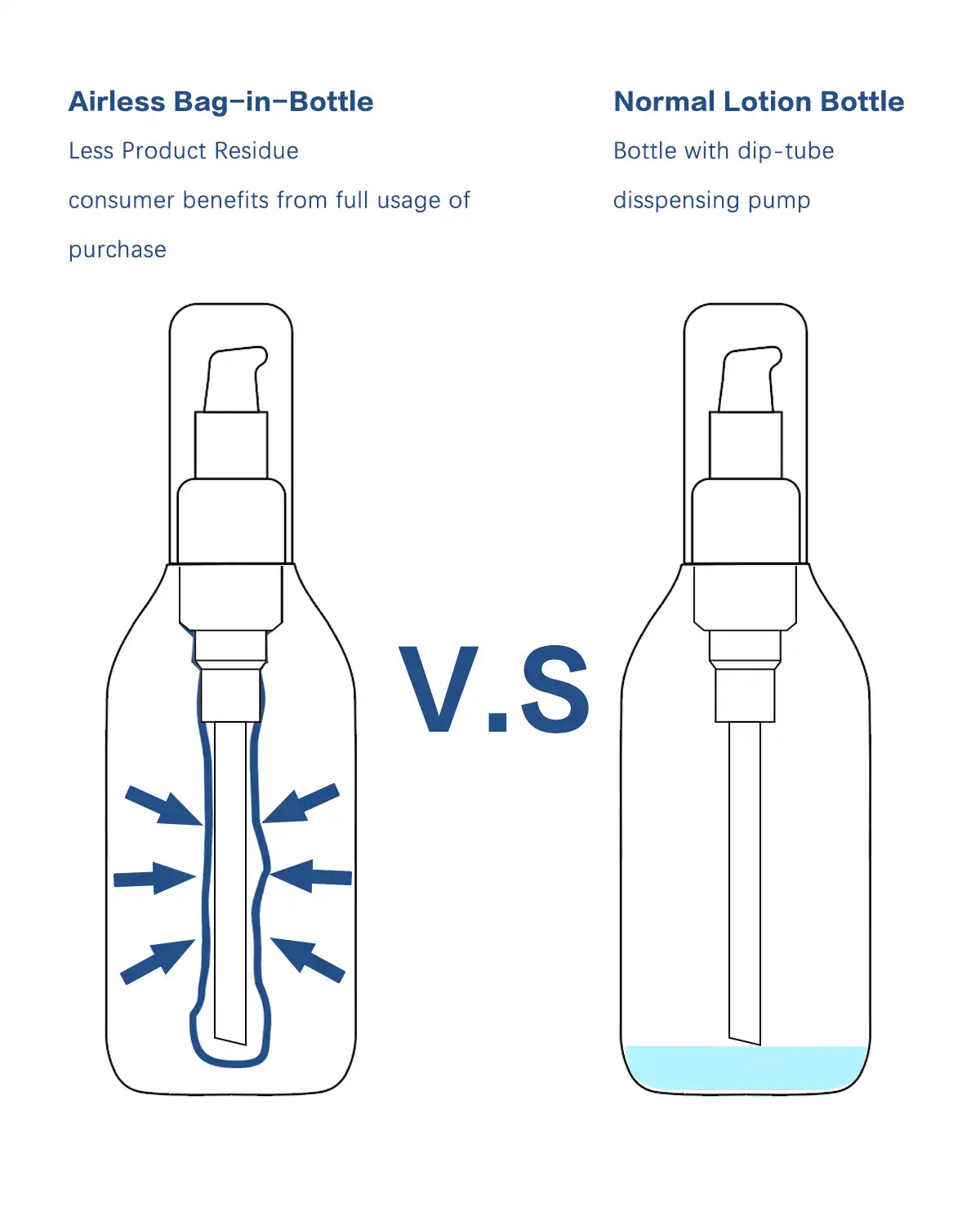

- Efficient product evacuation: Piston systems can dispense up to 95% of the product, minimizing waste and reducing the risk of bacterial growth in residual product.

- Versatility: Piston designs can accommodate a wide range of product viscosities, from light serums to thick creams.

Contamination prevention in bag-in-bottle systems

Bag-in-bottle designs offer their own set of contamination prevention benefits:

- Complete product isolation: The flexible pouch keeps the product entirely separate from the outer environment.

- No air ingress: As the pouch collapses, there's no opportunity for air to enter the product container.

- Suitable for ultra-sensitive formulas: The complete separation of product from the outer container makes this design ideal for highly reactive or unstable ingredients.

While both systems effectively prevent contamination, the choice between them often depends on specific product requirements, such as viscosity, sensitivity to air, and dispensing precision needs.

Topfeelpack's piston design for sensitive skincare formulas

Topfeelpack, a leader in innovative packaging solutions, has developed advanced piston-based airless packaging systems specifically tailored for sensitive skincare formulas. Their design addresses the unique challenges posed by delicate and reactive ingredients commonly found in high-end skincare products.

Advanced features of Topfeelpack's piston design

Topfeelpack's piston-based airless bottles incorporate several key features that set them apart:

- Precision engineering: The piston mechanism is designed to provide consistent and controlled product dispensing, crucial for active skincare ingredients that require precise application.

- Enhanced material compatibility: Utilizing materials that are inert and non-reactive, Topfeelpack ensures that their packaging does not interfere with the efficacy of sensitive formulas.

- Optimized air barrier: The design minimizes the air gap between the piston and the product, further reducing the risk of oxidation and contamination.

- Customizable options: Topfeelpack offers a range of sizes and designs to accommodate various product types and brand aesthetics, all while maintaining the integrity of their airless system.

Benefits for sensitive skincare products

The specialized piston design from Topfeelpack offers numerous advantages for sensitive skincare formulas:

- Extended shelf life: By minimizing air exposure, the packaging helps preserve the potency of active ingredients, extending the product's effectiveness over time.

- Reduced preservative requirements: The airless environment can allow for a reduction in preservatives, appealing to consumers seeking more natural or less processed skincare options.

- Improved hygiene: The sealed system prevents contaminants from entering the product, maintaining its purity throughout its use.

- Dosage control: Precise dispensing ensures that users apply the correct amount of product, maximizing efficacy and minimizing waste.

Topfeelpack's commitment to innovation in airless packaging technology has positioned them as a preferred partner for skincare brands looking to protect and enhance their sensitive formulations. Their piston-based designs offer a reliable solution for maintaining product integrity from production to the final use by the consumer.

Conclusion

The choice between piston and bag-in-bottle plastic airless packaging systems depends on various factors, including product formulation, viscosity, and specific preservation requirements. Both designs offer significant advantages over traditional packaging in terms of product protection and contamination prevention. Piston-based systems, like those developed by Topfeelpack, excel in versatility and efficient product evacuation, making them particularly suitable for a wide range of skincare and cosmetic applications. Bag-in-bottle systems, on the other hand, offer complete product isolation, which can be beneficial for ultra-sensitive formulas.

For brands in the skincare, cosmetics, and beauty industries, selecting the right airless packaging is crucial for maintaining product integrity and enhancing user experience. Topfeelpack's advanced piston design stands out as a superior choice for sensitive skincare formulas, offering precision, compatibility, and customization options that cater to the demanding needs of high-end and functional skincare products.

Are you a skincare brand owner, product manager, or supply chain professional looking for innovative packaging solutions? Topfeelpack offers fast customization, competitive pricing, and rapid delivery to meet your unique product needs. With our commitment to sustainability and advanced airless bottle technology, we can help you protect your formulas while aligning with market trends and environmental regulations. Experience the difference that Topfeelpack's airless packaging can make for your brand. Contact us today at pack@topfeelgroup.com to discuss how we can elevate your product packaging and preserve the efficacy of your skincare formulations.

References

- Johnson, M. (2022). Advancements in Airless Packaging for Cosmetics and Skincare. Journal of Packaging Technology and Research, 36(2), 112-128.

- Smith, A. L., & Brown, K. R. (2021). Comparative Analysis of Piston vs. Bag-in-Bottle Airless Systems in Preserving Sensitive Skincare Formulations. International Journal of Cosmetic Science, 43(4), 351-365.

- Davis, E. M. (2023). The Impact of Packaging Design on Product Shelf Life: A Focus on Airless Technologies. Packaging Science and Technology, 18(3), 205-220.

- Wilson, R. T., & Lee, S. H. (2022). Consumer Perceptions and Preferences in Cosmetic Packaging: The Rise of Airless Systems. Journal of Consumer Behavior, 25(1), 78-93.

- Thompson, C. L. (2021). Sustainability in Cosmetic Packaging: Innovations in Airless Designs. Green Chemistry and Sustainable Technology, 14(2), 180-195.

- Garcia, N. P., & Hernandez, M. A. (2023). Material Advancements in Airless Packaging for Enhanced Product Protection. Polymer Science and Engineering, 48(5), 412-428.

- 副本_1745399213966.webp)

_1747827716538.webp)